Cửa hàng

MÁY PHAY CẮT 2 ĐẦU RH-622RT

5 January, 2017

MÁY PHAY CẮT 2 ĐẦU RH-626ART

5 January, 2017

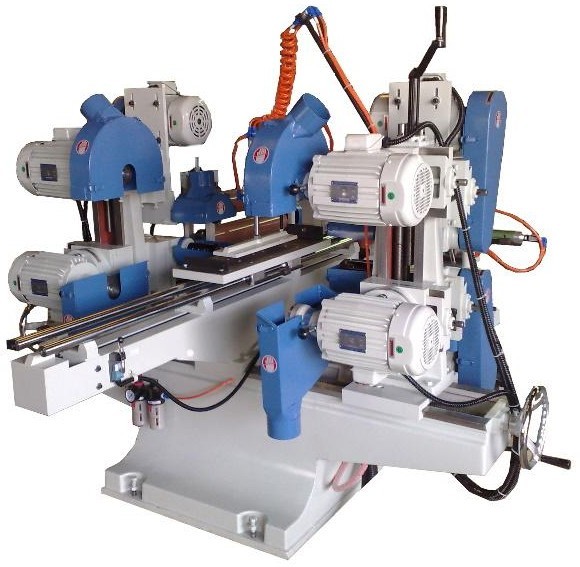

RH-424AR Double Ended Circular Sawing With Vertical Shaft Machine

1. The picture shown is an automatic model.

2. Sawblades and molder cutters are equipped at both ends providing trimming, size cutting, molding and tenoning operations-all quickly done in a single pass.

3. Standard models provide 4~8 feet length capacity to choose from. A custom model with over 8 feet capacity is available.

4. Separately mounted control box allows for moving into any position as desired.

5. Foot switch facilitates operational control. Feed speed is micrometrically adjusted.

6. Sawblades, cutting tools, automatic workpiece outfeed and manually operated air clamp cylinder are optional equipment.

7. Two rails configuration for models with over 4 feet cutting length increases cutting stability and accuracy.

| MODEL | RH-424AR | RH-624ART | RH-824ART |

| Processing Length | 250~1220mm | 500~1850mm | 500~2440mm |

| Processing Width | 580mm | ||

| Sawblade diameter (optional) | 250mm(10″)10”~14” | ||

| Tilting degree of sawblade and moulding spindle | 360° | ||

| Turning speed of circular sawing blade | 3000~3300R.P.M, 50~60Hz | ||

| No. of rails | 1set | 2set | 2set |

| Motor of circular sawing blade | 2HPx2 | ||

| Vertical shaft motor | 3HPx2 | ||

| Diameter of vertical shaft | φ30mm(Standard specification) | ||

| Turning speed vertical shaft | 6600~7200R.P.M. 50~60Hz | ||

| N.W./G.W. | 700/850kg | 950/1150kg | 1100/1300kg |

| Machine size | 2230x1920x1200mm | 2950x1920x1200mm | 3450x1920x1200mm |

| Shipping size | 2060x950x1400mm | 2820x1100x1400mm | 3500x1100x1400mm |