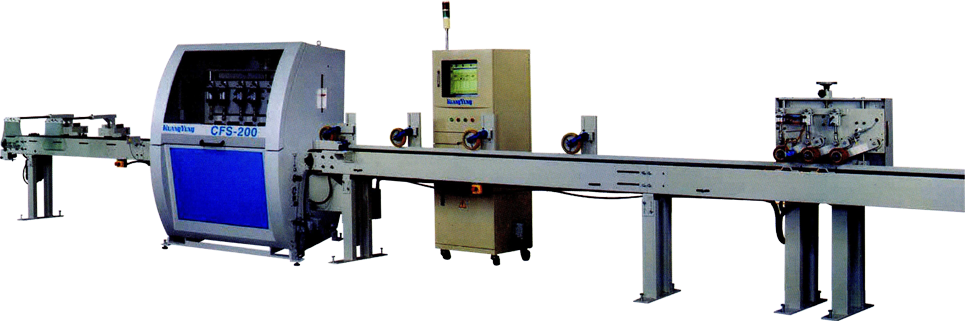

MÁY CƯA CFS-300

9 February, 2017MÁY CƯA SRS-300

9 February, 2017

| High Efficiency, Labor Saving Maximum Utilization of Material |

| Also employs a high speed computer control system that supplies accurate reports, allowing you to control your costs with ease. |

High speed feed rate of to 200m/min

Max. cut cycle of 180 cuts per min. |

|

|

| ADVANTAGE OF CFS-200B1(CNC) |

- CFS-200B is a computerized cut-off saw. It can make a optimum combination of material through the computer program operation (calculation). Thus to reach a maximum utilization of material.

- The User-friendly Program Operation is leading with “icon”. The user can understand how to operate each function easily.

- Allow to build different work sheets according to different customers and various kinds of wood and save as the exclusive files. Easy to do the addition and revision.

- The computer can calculate the percentage of effective wood, consumptive wood and waste, also, to sum up the cubic feet of wood. All data is showing with figure on the screen.

- The sorting system can be added the number of pushers according to the request of the customer. Also, the various lengths of outfeed mechanism are available for order.

- Using a special crayon to mark on the wood and being detected by the sensor during feeding, the machine cuts the defect wood automatically.

|

| CFS-200B1(CNC) Program Operation |

- The user must has the basic ability of operating “Microsoft Windows”.

- CFS-200B is a computerized cut-off saw. It can make a optimum combination of material through the computer program operation (calculation). Thus to reach a maximum utilization of material.

- The User-friendly Program Operation is leading with “icon”. Thus, the user can understand the usage of each function easily.

- Allow to build the different work sheets and save to its exclusive file. Also, it is easy to do the addition and revision.

- From the diagram of program, it can calculate the percentage of effective wood, consumptive wood and weste. Thus to count up the cubic feet of wood.

- The sorting system can sort out the length of wood effectively. (The sorting system is an optional equipment).

- The sorting system can be added the number of pushers according to the request of the customer. Also, the various lengths of outfeed mechanism are available for order.

- Employs Mitsubishi servo motor which feature compact construction, high speed response capability, high torque and comprehensive protection features.

- The tilted conveyor ensures workpiece feeds in straight and against the fence, preveting the workpiece from entering skewed.

- Usinig a special crayon to mark on the wood and being detected by the sensor during feeding, the machine cuts the defect wood automatically.

|

- Remaining material is cut to the optimized length according to various setting lengths.

|

|

Dimensions |

|

|

Specifications |

|

|

Model

|

CFS – 200B1(CNC)

|

| Saw motor |

7.5KW (10HP) |

| Feed motor |

7 kW (in total) |

| Powered bottom rollers |

7 |

| Top pressure rollers |

7 |

| Feed speed |

variable up to 200 m/min. |

| Saw blade diameter |

Ø455 mm (18″) ~ 505 min (20″) |

| Working height |

900 mm |

| Dust outlet diameter |

150 mm x 1 |

| Max. timber infeed |

6500 mm |

| Min. timber infeed |

500 mm |

| Cross section cutting |

See cutting diagram |

| Cutting accuracy |

0.5~ 1.5 mm

(Depending on timber plane, resin and bend of the board) |