Store

MOTOR CARPET AND INNER SOFT COMPONENTS COMPRESSION FORMING KTM-100

2 March, 2017

PLATE-TYPE HYDRAULIC MACHINE EHP-1200

2 March, 2017More-Details:

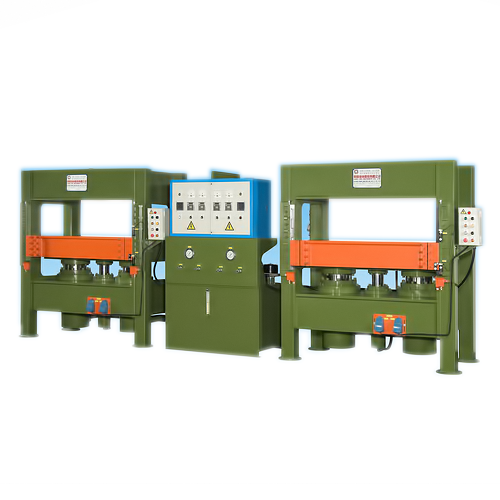

Sawdust Press Forming Machine (One set with two machines it can share with one oil tank.) Pressure﹕100-1000 Tons Applications﹕Hot-pressed boards are used for making engraved door panels, cabinet door panels, ceilings, mirror frames, tabletops, chair seat panels, floorings, and toilet covers.

- Machine Feature﹕

- Machine is using firm welding. The strength of machine’s fuselage is especially well. When machine is compressing, the fuselage deformation is extremely few. Relatively the compression product will be smooth, no curving, no distort.

- Machine is using synchronous hydraulic cylinder. It can raise the movement speed, increase production efficiency. Relatively using synchronous hydraulic cylinder the hydraulic circuit structure will also reduce the hydraulic horsepower. It will achieve the biggest efficiency for energy conservation.

- Two machines share with one hydraulic oil system. It’s also can saving the occupy space, and the special design of hydraulic circuit will not affect the two machines operation.

- The unique design of hydraulic circuit can let the machines working extremely silent.

- HMI controlling, multi-function options and operation, it will security conform the variety produce production.

- The firm fuselage, the high quality components select, it will make machine reduce the failure, and the long period use. It can make sure the product quality and the stability of delivery time.

|

Tons |

250 Tons |

350 Tons |

500 Tons |

|

Table size |

1500 * 1000 mm |

1880 * 1060 mm |

2400 * 1060 mm |

|

Open distance |

450 mm |

520 mm |

620mm |

|

Main cylinder |

270 * 450 stroke * 210 kg/cm² * 2 pcs |

335 * 550 stroke * 210 kg/cm² * 2 pcs |

335 * 550 stroke * 210 kg/cm² * 3 pcs |

|

Speed cylinder |

125 * 80 * 450stroke * 210 kg/cm² * 1 pcs |

140 * 550 stroke * 210 kg/cm² * 1 pcs |

100 * 550stroke * 210 kg/cm² * 2 pcs |

|

Motor |

10HP * 6P |

15HP * 4P |

20HP * 4P |

|

Attach with automatic hydraulic circuit. |

|||

|

Electric box |

PLC HMI controller |

||