Store

H CLASS- DOUBLE END TENONER

29 December, 2016

NC TYPE DOVETAIL TENONER DE NC 600 | THUONG NGUYEN

29 December, 2016APPLICATION

– The DET series Double End Tenoner are designed for those factories who manufacturing panel ,solid wood housing material.

– The DET series feature of sequence range for mass production and perfect sizing , trimming cut for wood block & narrow panel! machine includes scoring saw, main saw, moulding unit .

– The working stock of the DET series is no limit for longitudinal wise.

– The working width can be of min. for 220 mm (optional on request 180 mm) upto max. for 1300 mm / 2000 mm / 2600 mm versions.

– The working thickness concerned is standard with 100 mm.

– Which be used on solid & panel wood furniture like OA furniture, kitchen, door & windows, wood & laminate flooring production and etc.

FEATURES

- Heavy and rigid constructure to ensure sizing, squaring and tenoning with high precision and productivity.

- The bed carrying with high precision linear guide way to get perfect parallel at x-axis.

- Feed chain track system is enriched with precision track linkage which mounted with dust-proof and free lubricated needle to ensure perfect parallel at y-axis.

- The high precision linear guide way + feed chain track to form the double crisscross movement to guarantee squaring.

- High accurate needle bearing mounted in precision chain track linkage for dust-proof and free lubrication.

- Electric positioning device with digital readout in metric, inch for various operation. No micro-adjustment required.

STANDARD ATTACHMENT

- Auto. positioning device for movable stand to control working width.

- Digital readout device for thickness adjustment of double side, 2 pcs/set.

- Digital readout device for vertical adjustment of workheads, 6 pcs/set.

- Digital readout device for horizontal adjustment of workheads, 6 pcs/set.

- Feed chain track with rubber pad.

- Scoring saw blade 205×25.4×3.0mm x t80 – 2pcs.

- Main saw blade 305×25.4×3.0mm x t100 -2pcs.

OPTIONAL ATTACHMENT

- Additional cost for wooden case.

- Feed chain track with phenolic pad instead of rubber pad.

- Feeding system with strengthen support.

- Center support.

- Center support with auxiliary top pressure roller.

- Laser beam for cutting line indication.

- Safety cabinet for CE ARE standard.

- Additional dog for feed chain track.

- Distance between centers of bottom chaintrack sprocket and top belt pulley change from 430 mm to 830/1130mm. (4/6 working unit series)

- Jumping device for scoring saw unit.

- Scoring saw motor increased to 3HP/5HP.

- Main saw motor increased to 7.5HP.

- Profile moulding motor increased to 7.5HP.

- Profile moulding unit with pneumatic top pressure

- Pad + Bottom support (chrom plated).

- Manual lubrication system.

- Auto. lubrication system.

- Moulding cutters 150x30x40mm x 6t.

- Flooring cutters 137x30x20mm x 6t.

- Hogging cutters.

- Auto. feeding magazine.

- Pre-milling cutter for scoring & main saw (fixed sied).

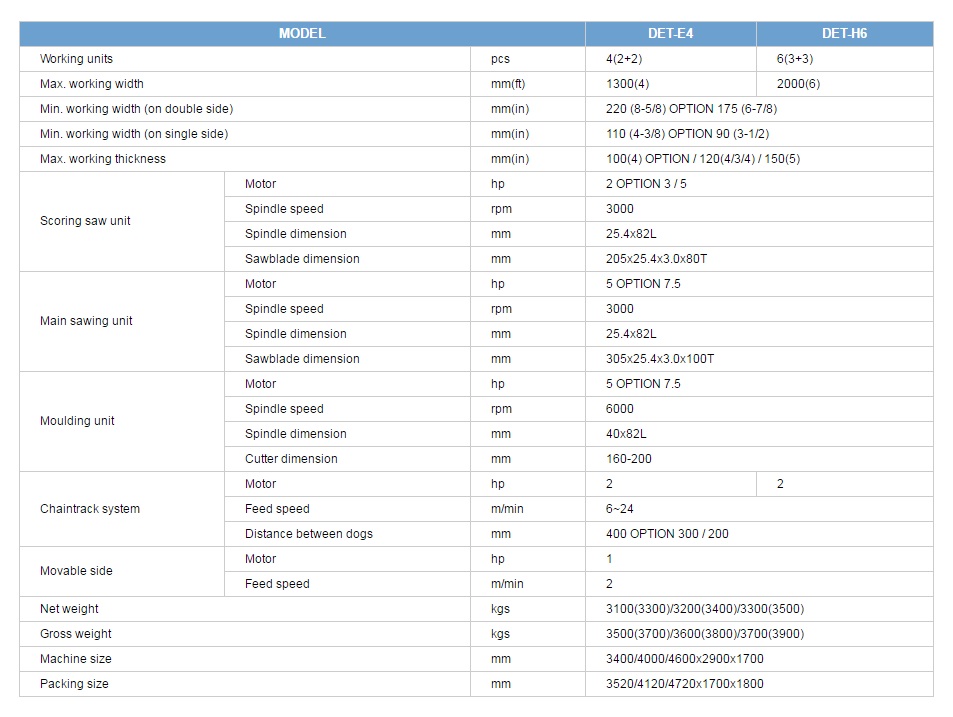

TECHNICAL