Store

HIGH FREQUENCY WOOD BOARD JOINTING MACHINE AND FULL AUTO SYSTEM KHL-1030H

29 December, 2016

FINGER JOINT MACHINE FJ – 460L

29 December, 2016

Product Specifications

●= Standard / o(—) = Optional / – = No configuration / F = Fully automatic configuration / H = Configure the pre-joint system / B = Configure rear feeding conveyor system / C = Simple Conveyor Configuration / 2L = Double finger assembler configuration

Features

-

Shaper’s machines body are more stable and parts standardization.

-

Linear slides change in the side of machine, strengthening the stability of the shaper’s move carriage.

-

Enhance the strength of hydraulic cylinder shaft.

-

Saw shaft tube holder to casting, the material is more stable, saw the axis of the material change using Japanese blue steel(Nickel Chromium Molybdenum Alloy Steel JIS G4103-1979), structural change and the same vertical finger spindle, and the drive belt was changed timing belt.

-

Roller conveyor system the roller diameter down to 60mm and increase strength, so that make the short material through more stable!

-

New model of glue applicator, the old system is using air pressure tank change to air cyclinder to squeeze out of glue. That has five times of pressure than air tank output.

-

Finger assembler, front section-in feed device has change to 5 sets of in-indde roller with independent cylinder and yaw press system.

-

Control methods change to HMI control panel.

Thông số :

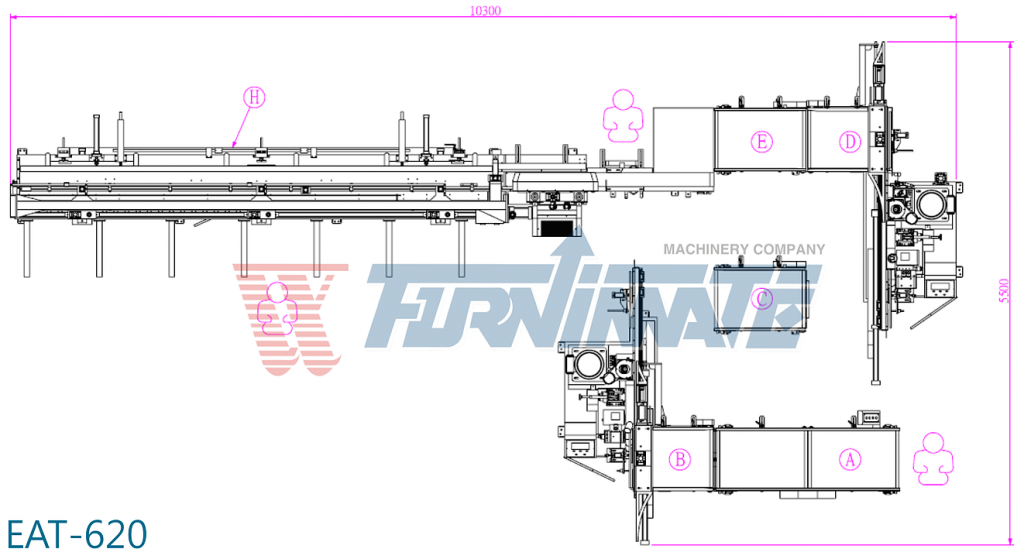

A&C&E. BĂNG TẢI CẤP PHÔI

- Kích thước băng tải : W620 x L900mm

- Motor : 1/2 HP

B&D. MÁY PHAY FINGER (TRÁI & PHẢI)

- Kích thước bàn làm việc: W620 x L800 mm

- Chiều dài làm việc: 150 ~ 800 mm

- Chiều dày làm việc: 15 ~ 150 mm Motor truïc phay finger : 20HP moãi beân

- Motor trục lưỡi cưa: 5 HP moãi beân

- Motor trục lưỡi cưa mồi trên & dưới (TRÁI): 2 HP x 2

- Motor trục lưỡi cưa mồi phía dưới (PHẢI) : 2 HP

- Motor băng tải : ½ HP mỗi bên

- Motor bơm thủy lực: 3 HP mỗi bên

- Đường kính trục bôi keo: 100mm

- Công suất: 3 ~ 4 lần đánh/phút

H. Máy ghép dọc tự động

- Chiều dài làm việc: 5200 mm

- Chiều rộng làm việc: 150 mm

- Chiều dày làm việc: 75 mm

- Motor lưỡi cưa: 5HP

- Motor cuốn phôi: 2 HP

- Motor bàn cấp phôi: 2HP

- Inverter : 5HP

- Motor bơm thủy lực: 5 HP

- Năng suất : 3 ~ 6 thanh/phút