Store

TILT BAND RESAWS (HP-345T)

8 February, 2017EDGE BANDING MACHINE EUROPE – PRO13

8 February, 2017EDGE BANDING MACHINE | MULTI-FUNCTIONS | EUROPEAN | PRO-12

⭐⭐⭐⭐⭐

✅ Functions: 8 functions + Optional

✅ Heavy-Duty, using Advanced European Technology

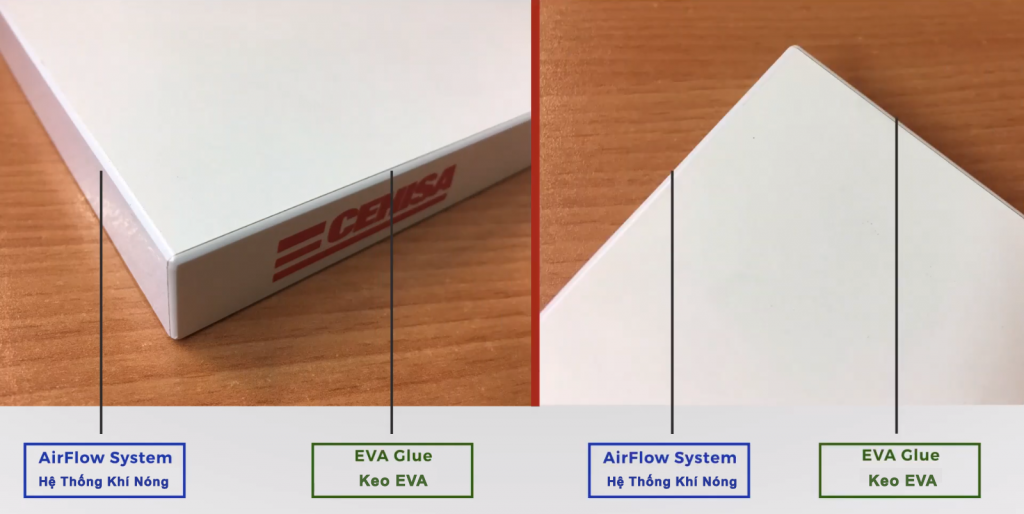

✅ Produces result: with NO VISIBLE GLUE LINE (OPTIONAL AirBlow System REQUIRED)

(☞゚ヮ゚)☞ Fantastic result + Very durable + Stable workflow + Longlasting professional aftersale services ???

✨ AUTOMATIC EDGE BANDING MACHINE | MULTI-FUNCTIONS ✨

⭐⭐⭐⭐⭐

✨ HIGHLIGHTS:

- Automatic edge banding machine.

- Controlled by touch screen PLC 10″.

- Configured with 8 functions, including Corner Rounding Unit.

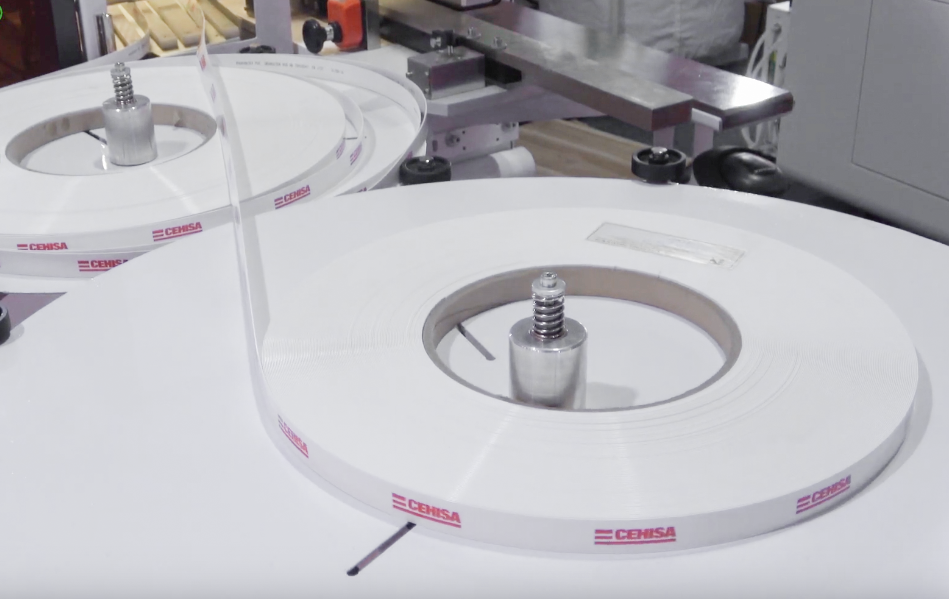

- Edge strip types: PVC, ABS, PP, Acrylic, Natural Veneer, Aluminium, High Gloss and 3D from 0.4mm to 3.0mm, Solid Wood up to 8mm.

- Panel types: MCF, MDF, XPS, Foam Board, thickness from 8mm to 60mm.

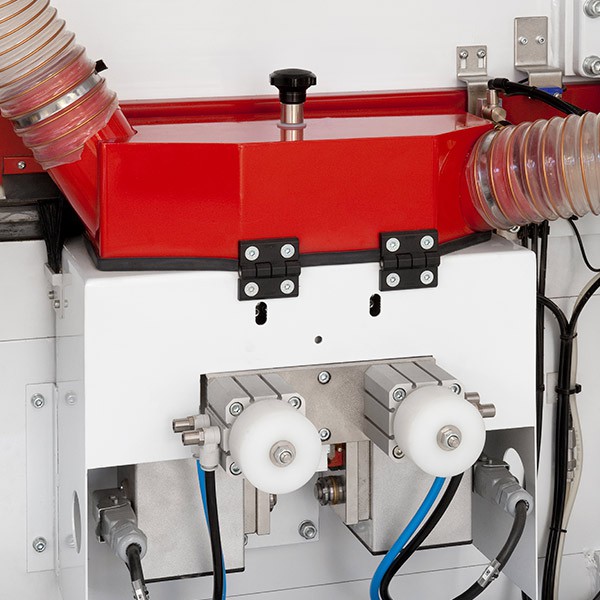

- Adhesives: EVA, PUR, PO.

- Heavy-duty, suitable for factories with heavy production.

- Very durable and stable. ???

- Can output products with no visible glue line (Requires OPTION AirFlow System, details below).

- European technology.

? FEATURES:

|

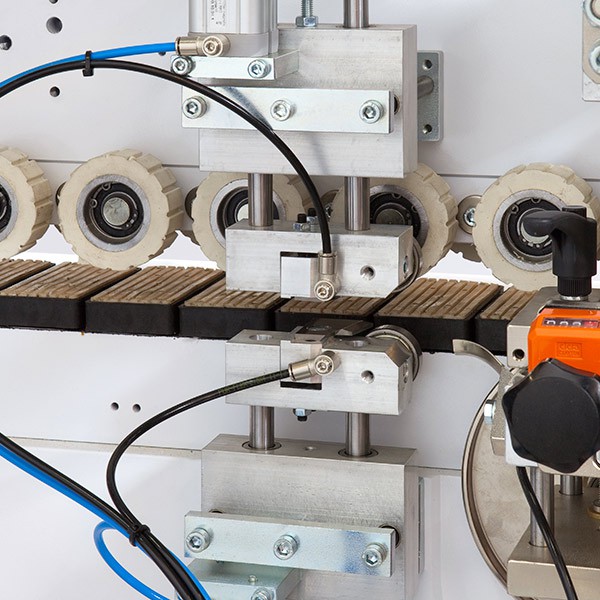

[ Premilling ]

|

|

[ Gluing ]

✨ Use OPTION Duo-Melt (details below) to switch adhesive usage between EVA and PUR quickly and conveniently. ✨

|

|

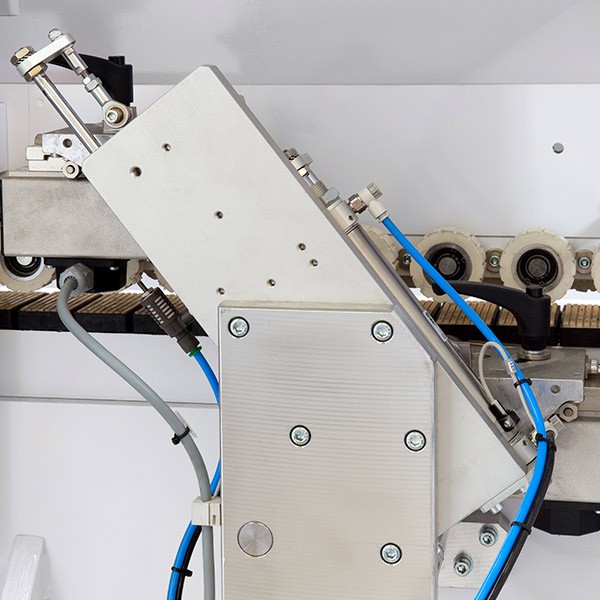

[ Endtrimming ]

|

|

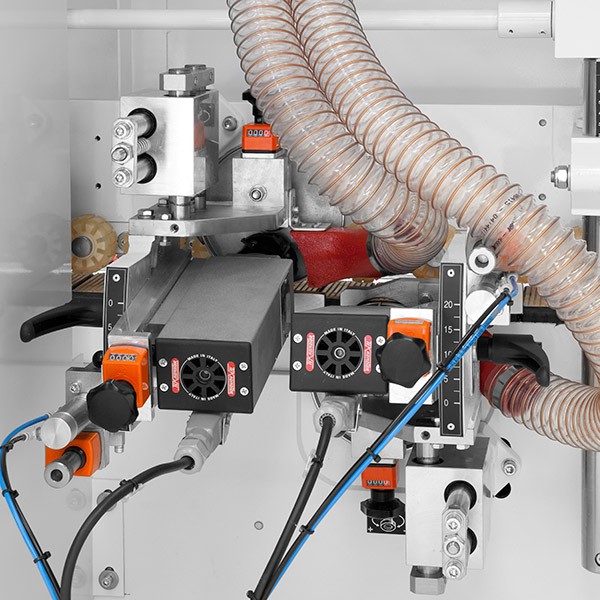

[ Trimming ]

|

|

[ Corner Rounding ]

|

|

[ Radius Scrapper ]

|

|

[ Glue Scrapper ]

|

|

[ Buffing Unit ]

|

|

✨ OPTIONAL FEATURES / UNITS ✨ |

|

|

[ Non-stick Agent Spray ] OPTIONAL

|

|

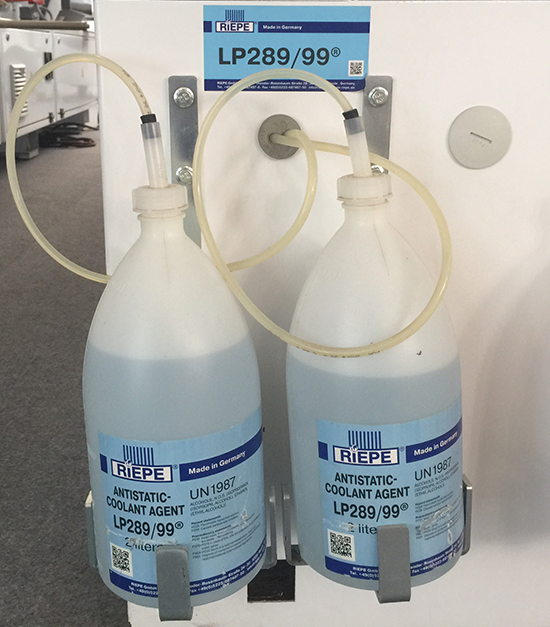

[ Antistatic Agent Spray ] OPTIONAL

|

|

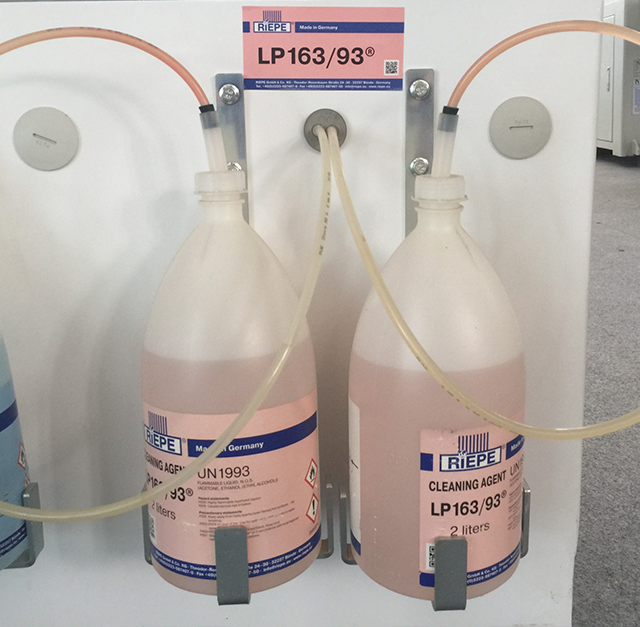

[ Cleaning Agent Spray ] OPTIONAL

|

|

[ Duo-Melt ] OPTIONAL

|

|

[ Double Edge Feeding ] OPTIONAL

|

|

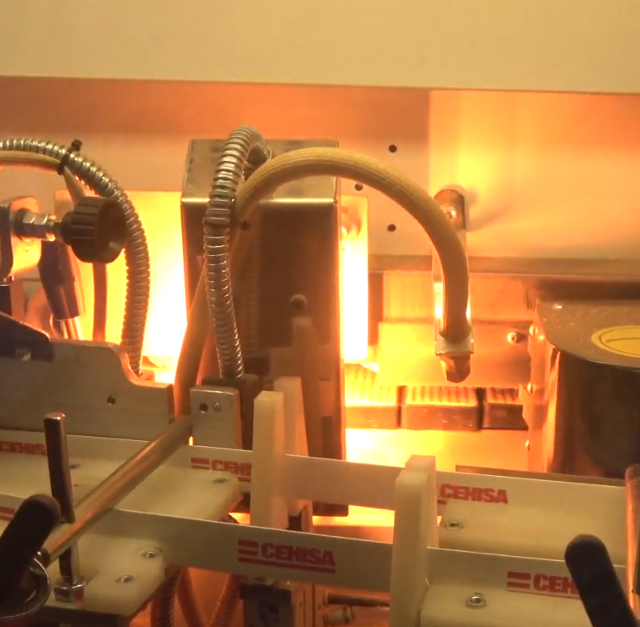

[ Infrared Lamp ] OPTIONAL

|

|

[ Barcode Reader ] OPTIONAL

|

| AIRFLOW SYSTEM (No Glue Line)

OPTIONAL Click here for more details

Click here for more details |

|

? VIDEO: QUALITY AUTOMATIC EDGE BANDING MACHINE

? TECHNICAL SPECIFICATIONS: AUTOMATIC EDGE BANDING MACHINE

MODEL: PRO-12

| Edge band thickness (rolls / wood strips) | 0.4 – 3.0 mm (Max. 8mm with option) |

| Edge band width | 13 – 65 mm |

| Panel thickness | 10 – 60 mm |

| Min. panel length | 120 mm (200 mm with CR unit on) |

| Min. panel width | 75 mm |

| Working feedrate (2 modes) | 9 or 14 m/min |

| Electrical connection |

|

| Total power installed (Basic functions) | 12.9 kW |

| Compressed air connection | 6 – 7 bar |

| Machine dimensions | 5618 x 660 x 1485 mm |

| Packaging dimensions | 5600 x 990 x 1740 mm |

| Net / Gross weight | 1500 / 1875 kg |

? CONTACT US:

If you would like to acquire this machine or have any question about edge banding machine & woodworking machine in general, please contact us via:

✨ Hotline: (+84) 902 98 58 98

? Sale Department:

(+84) 898 945 946

(+84) 933 703 227

(+84) 931 775 220

(+84) 931 775 221

? Email:

woodwm@thuongnguyen.vn

salesmanager@thuongnguyen.vn

And visit our Youtube and Facebook for videos, news, and woodworking related content!

? Youtube: https://www.youtube.com/c/MÁYCHẾBIẾNGỖTHƯỢNGNGUYÊN

? Facebook: https://www.facebook.com/tnmaychebiengo/

? Twitter: https://twitter.com/MYCHBING1

⭐⭐⭐⭐⭐