MACHINE IN LINE

|

Image

|

1. AUTOMATIC BOWLING MACHINE – 100%

BRAND: GOODTECH – MADE IN CHINA

Machine size: 6000 x 3000 x 3800 mm

Working height: 100-1500 mm

Servo motor: X 1kW, Z 2kW

Weight: 1400 Kg

Door lifting capacity: < 60 Kg

|

|

|

2. CONVEYOR BELT – 100%

BRAND: GOODTECH – MADE IN CHINA

Used for centering and positioning during the board transfer process

Can center the wooden door layer without pre-cutting

Size: 3000 x 1300 x 900 (±50)

Main beam specifications: 240*50 aluminum bars

Roller diameter: Þ56

Glue thickness: 3 mm

Distance between rubber rollers: Þ180

Load capacity: 100 Kg

Speed: 10 – 28 m/min

|

|

|

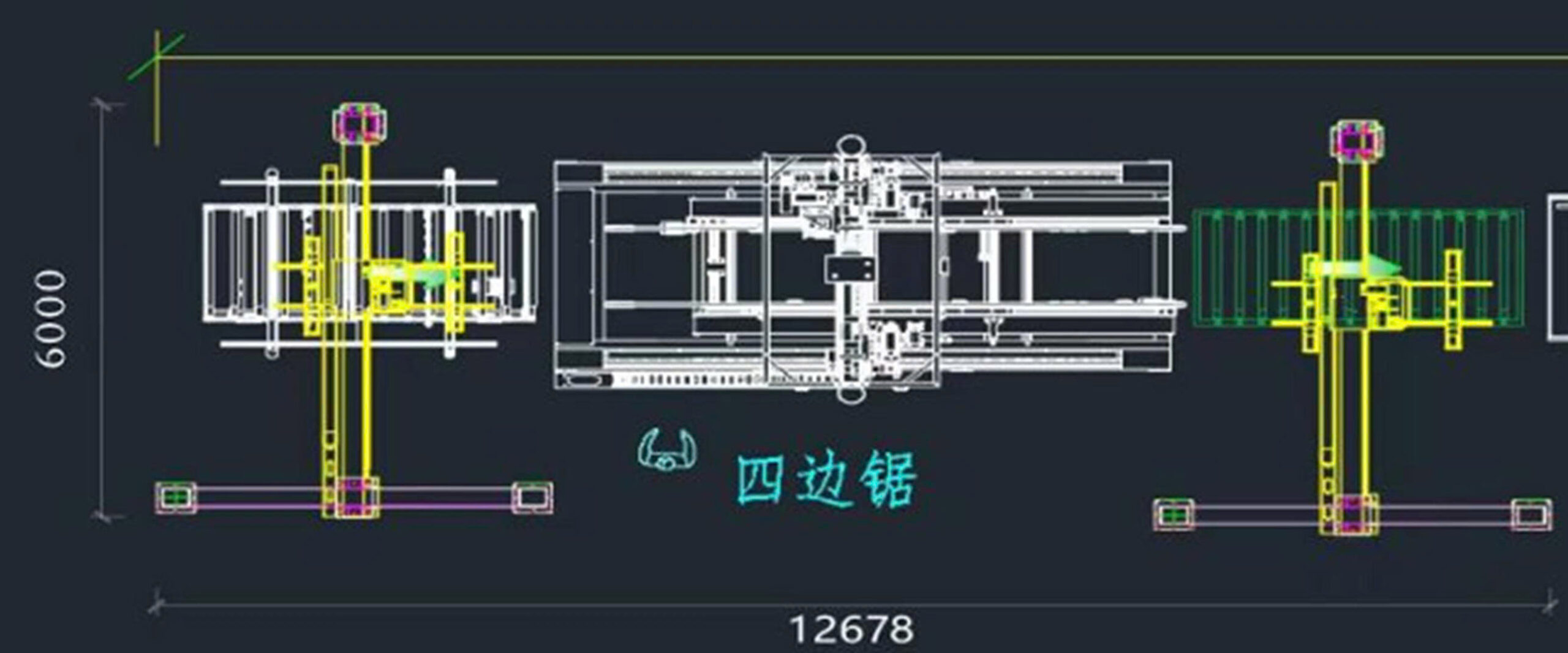

3. DOOR EDGE CUTTING MACHINE – 100% (INCLUDING SCANNING)

BRAND: GOODTECH – MADE IN CHINA

3 machine heads (large and small saw blade groups)

Automatically adjust on door strip

Door width: 450-1100 mm

Maximum door length: 3000 mm

Door thickness: 30-60 mm

Panel length: 1600-3000 mm

Main saw motor: 7.5KW, D300mm-d30mm

Saw motor: 1.5KW, D120mm-d22 mm

Machine size: 4700 x 2800 x 2300 mm

|

|

|

4. CONVEYOR BELT – 100%

BRAND: GOODTECH – MADE IN CHINA

3000*1300*900 (±50)

Main beam specifications: 240*50 aluminum profile

Roller diameter: Þ56

Glue thickness: 3mm

Roller distance: Þ180

Load capacity: 100kg

Whole line speed: 10-28 m/min

|

|

|

5. AUTOMATIC BOWLING MACHINE – 100%

BRAND: GOODTECH – MADE IN CHINA

Machine size: 6000 x 3000 x 3800 mm

Working height: 100-1500 mm

Servo motor: X 1kW, Z 2kW

Weight: 1400 Kg

Door lifting capacity: < 60 Kg

|

|

MACHINE OPERATION VIDEO:

👨🔧Contact us now for free consultation and attractive offers!

☎️Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG