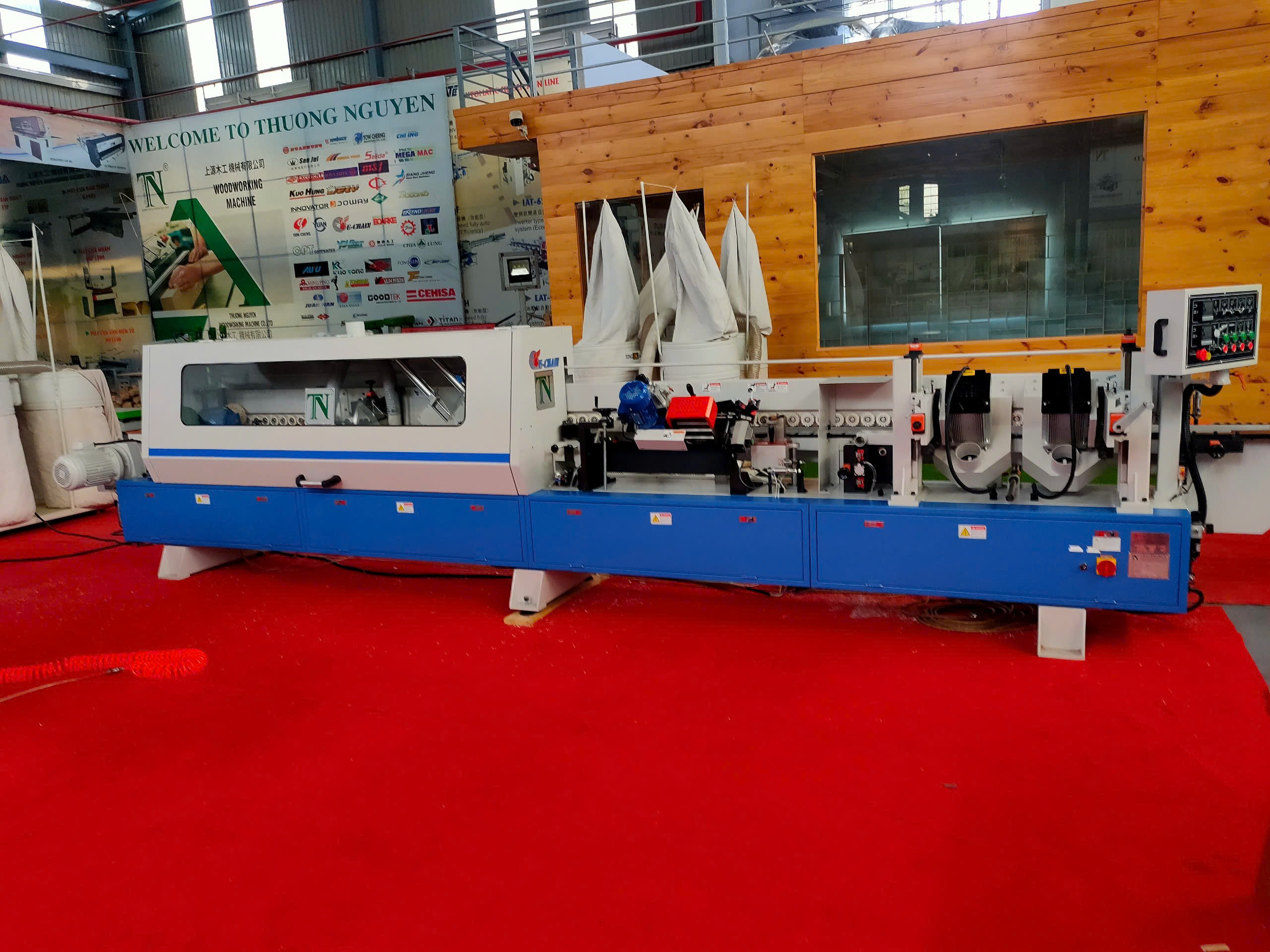

🪵 AUTOMATIC EDGE BANDING MACHINE – MODEL: RFB565JC

Advanced Technology – Stable Operation – High-Quality Finish

⚙️ MAIN FUNCTIONS

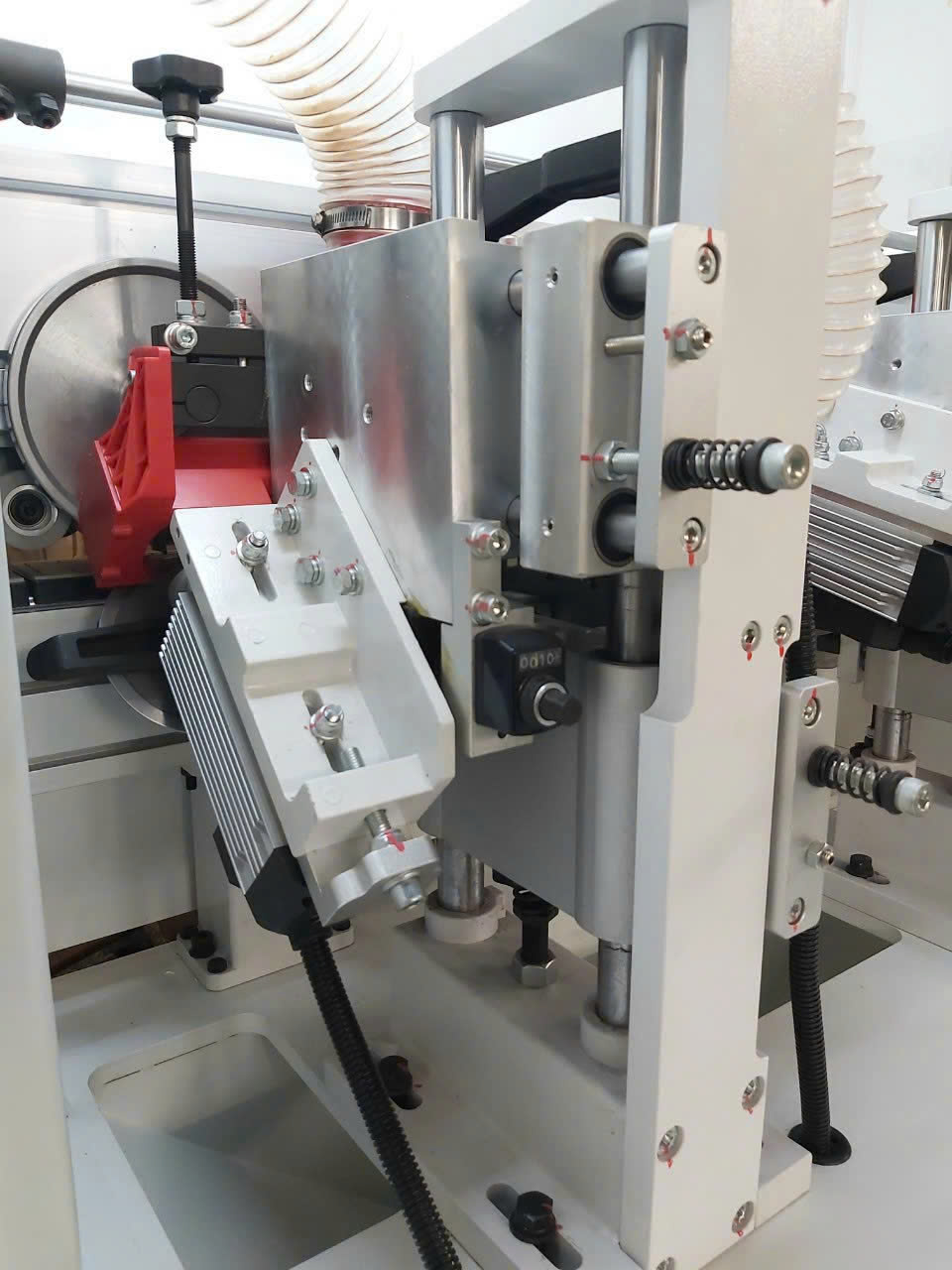

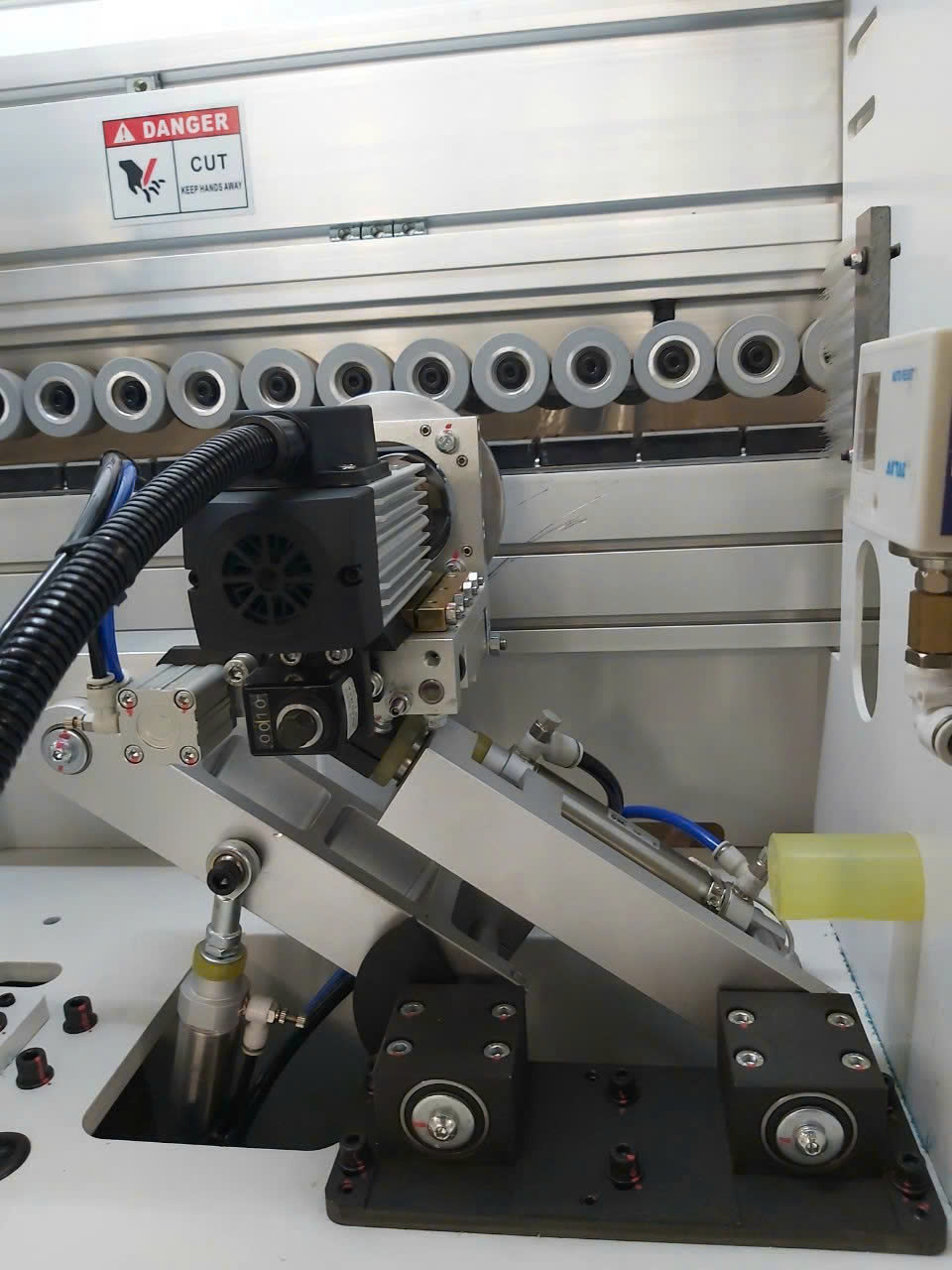

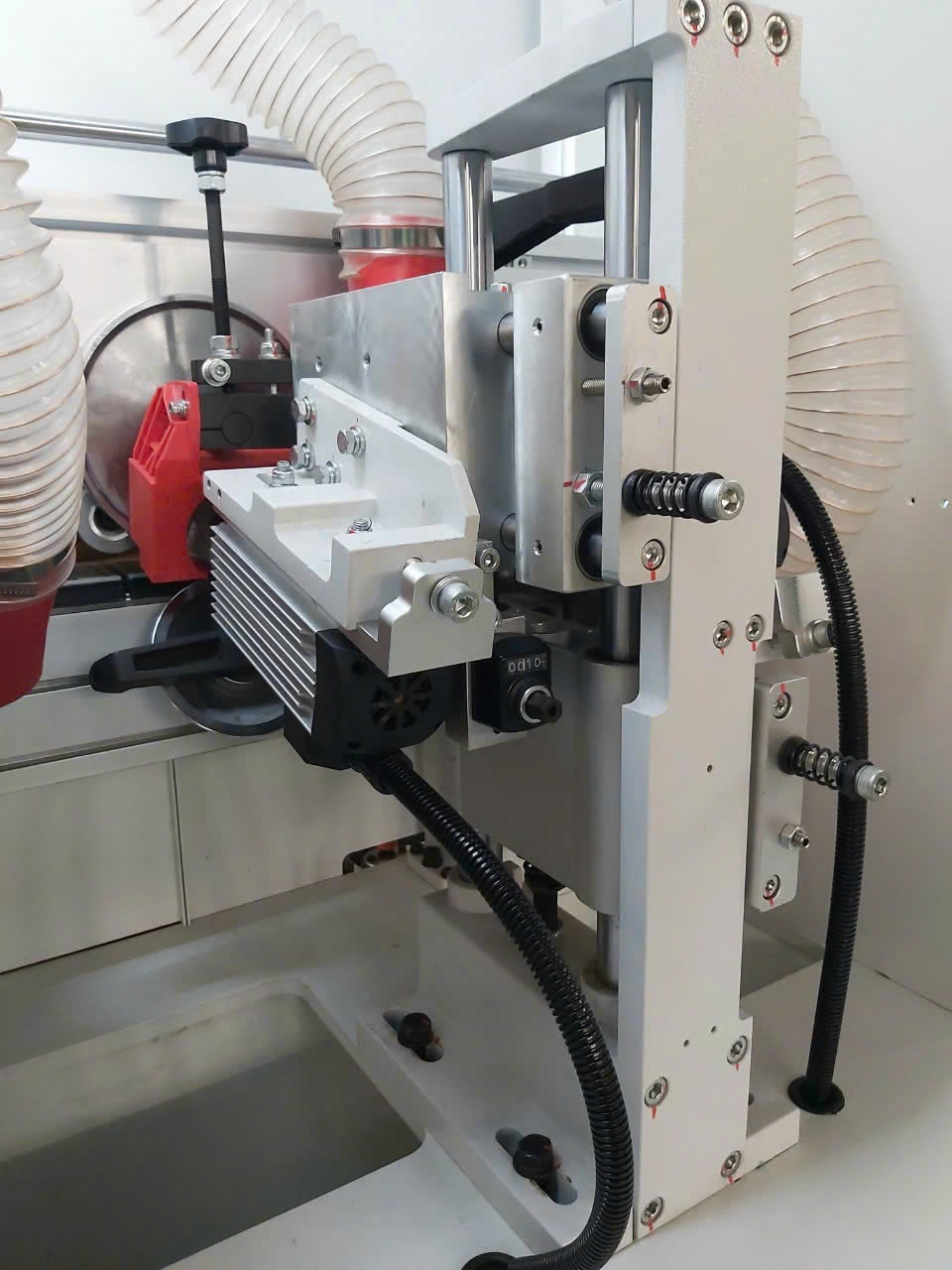

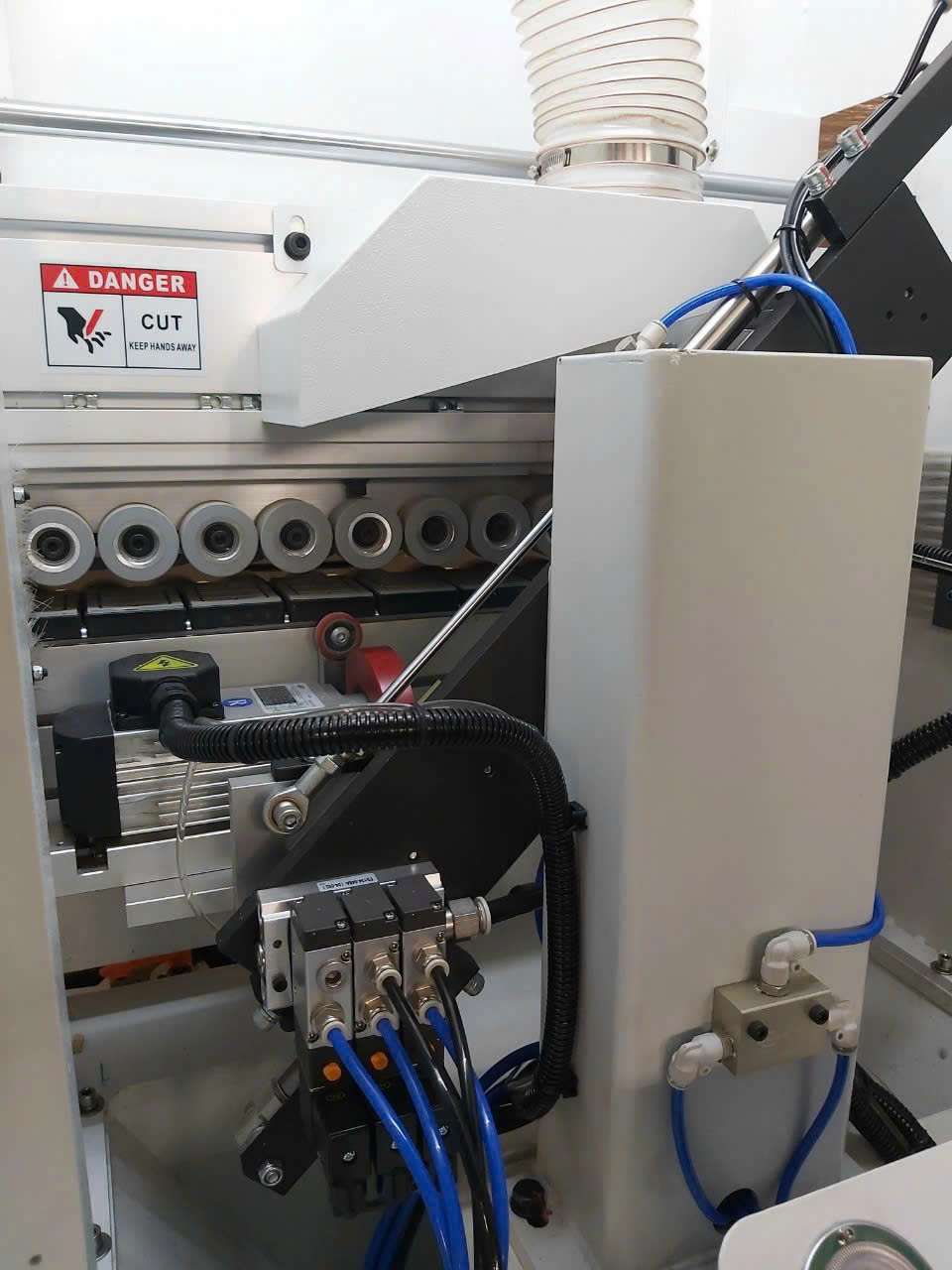

✅ Pre-milling – Cleans and flattens the edge surface for optimal adhesion

✅ Glue Application – Automatic and consistent glue spreading

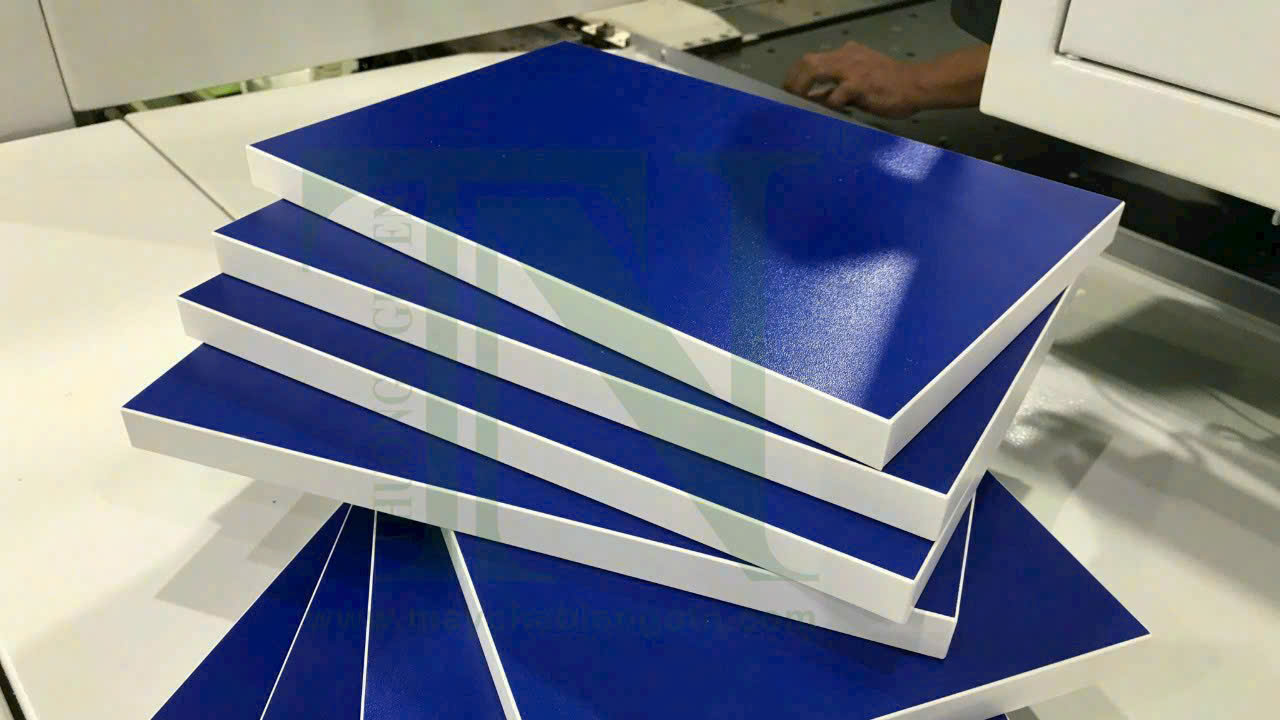

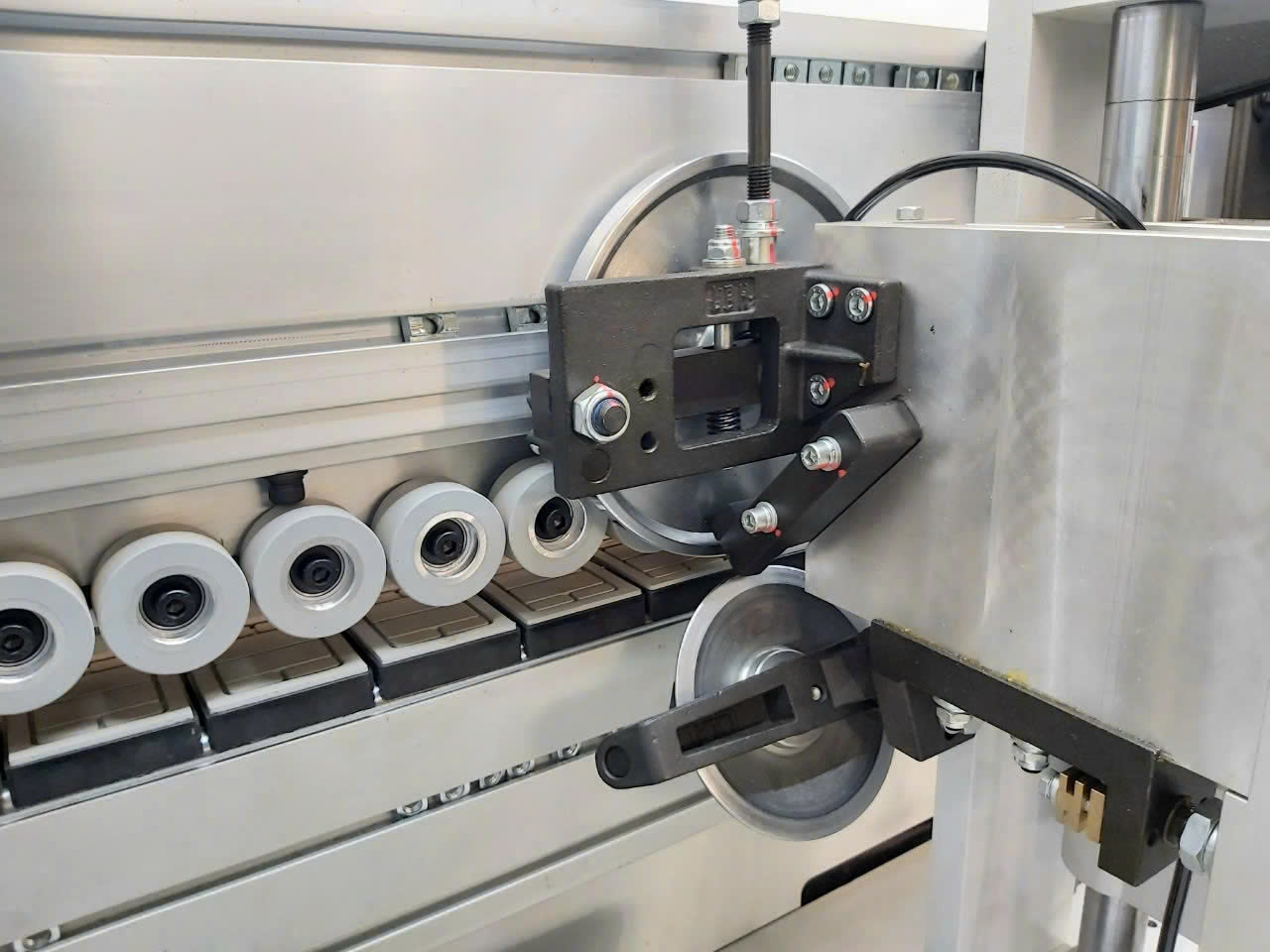

✅ Edge Banding – Edge Trimming – End Cutting – Fully automatic and precise

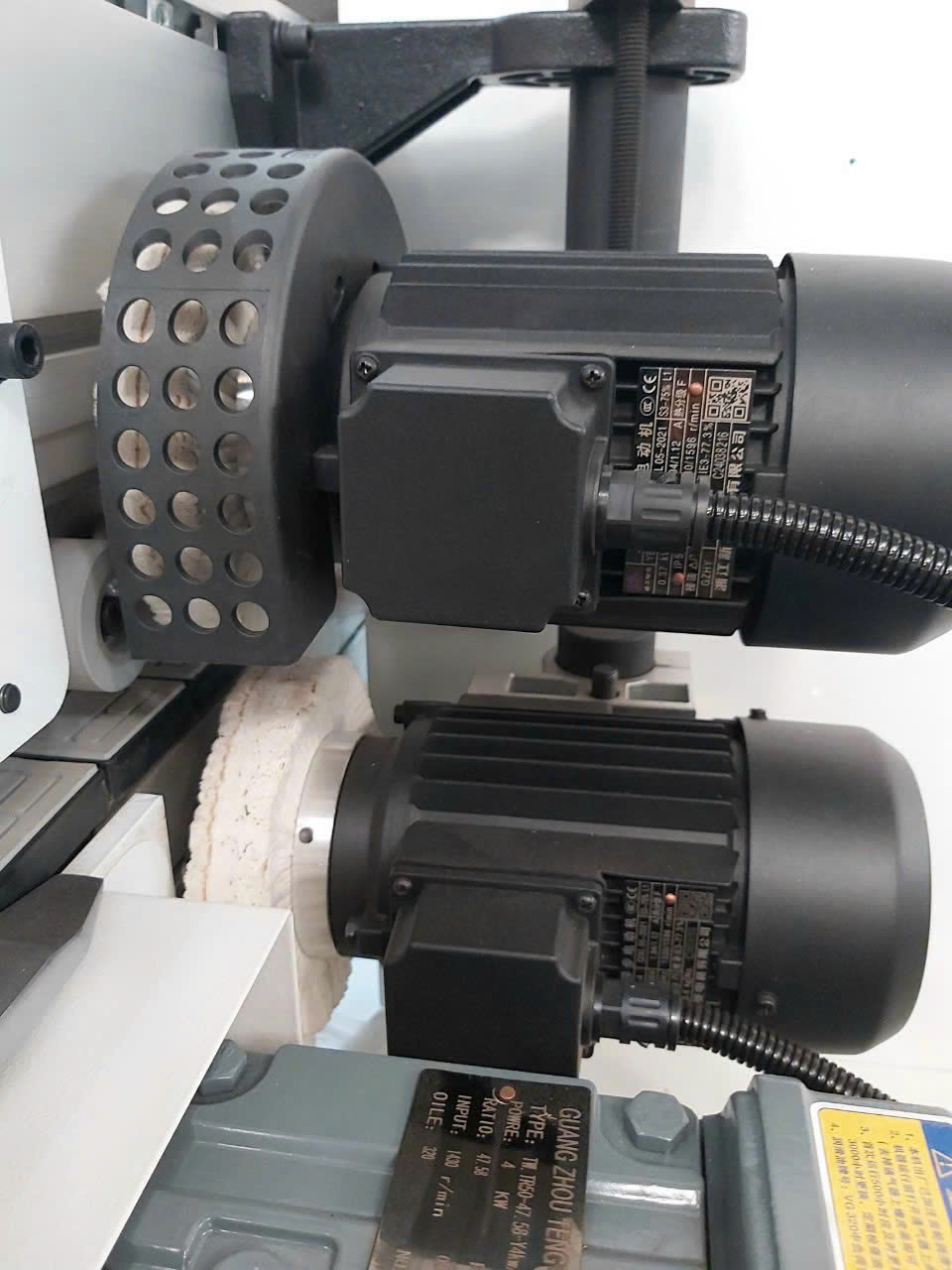

✅ Rough & Fine Trimming – Corner Rounding – Smooth, sharp edge finishes

✅ Glue Scraping – Buffing – Clean surfaces without glue excess, perfect aesthetics

📏 TECHNICAL SPECIFICATIONS

| Specification |

Value |

| Operating Voltage |

380V, 50Hz, 3-Phase |

| Edge Band Thickness |

0.4 – 3 mm |

| Panel Thickness |

10 – 60 mm |

| Minimum Panel Width |

60 mm |

| Minimum Panel Length |

150 mm |

| Conveyor Speed |

16 / 20 / 23 m/min (adjustable) |

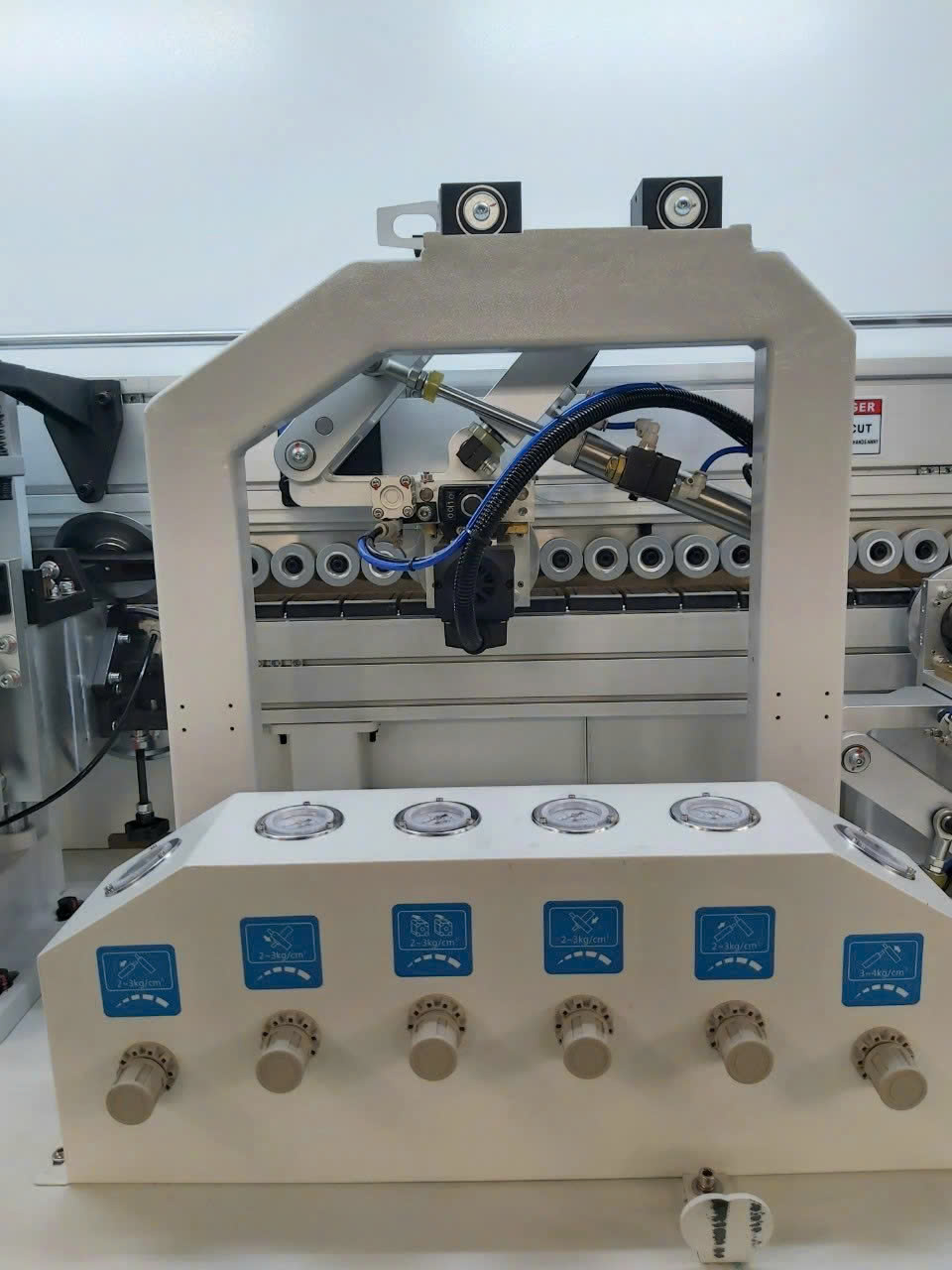

| Working Air Pressure |

6.0 bar |

| Total Power |

15 kW |

| Machine Weight |

2,280 Kg |

| Packing Dimensions |

7300 x 1200 x 1680 mm |

🎯 KEY ADVANTAGES

-

Fully automated – Reduces labor costs

-

Easy-to-use control interface

-

Smooth, strong, and beautiful glue lines

-

Durable and ideal for large-scale production

📌 APPLICATIONS

👉 Ideal for furniture factories, MDF/plywood door production, partition walls, kitchen cabinets, office desks, etc.

👉 Compatible with multiple types of edge bands: PVC, ABS, Veneer, Melamine

👨🔧 Contact us now for free consultation and attractive offers!

☎️ Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG