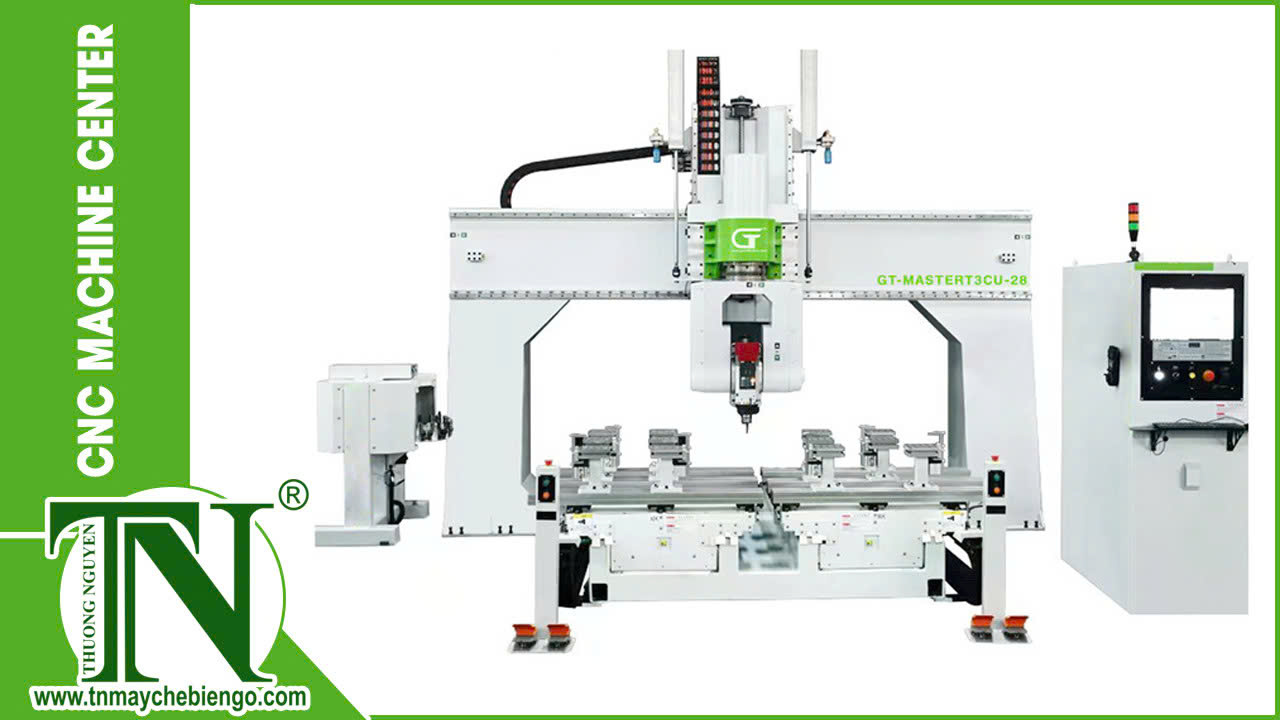

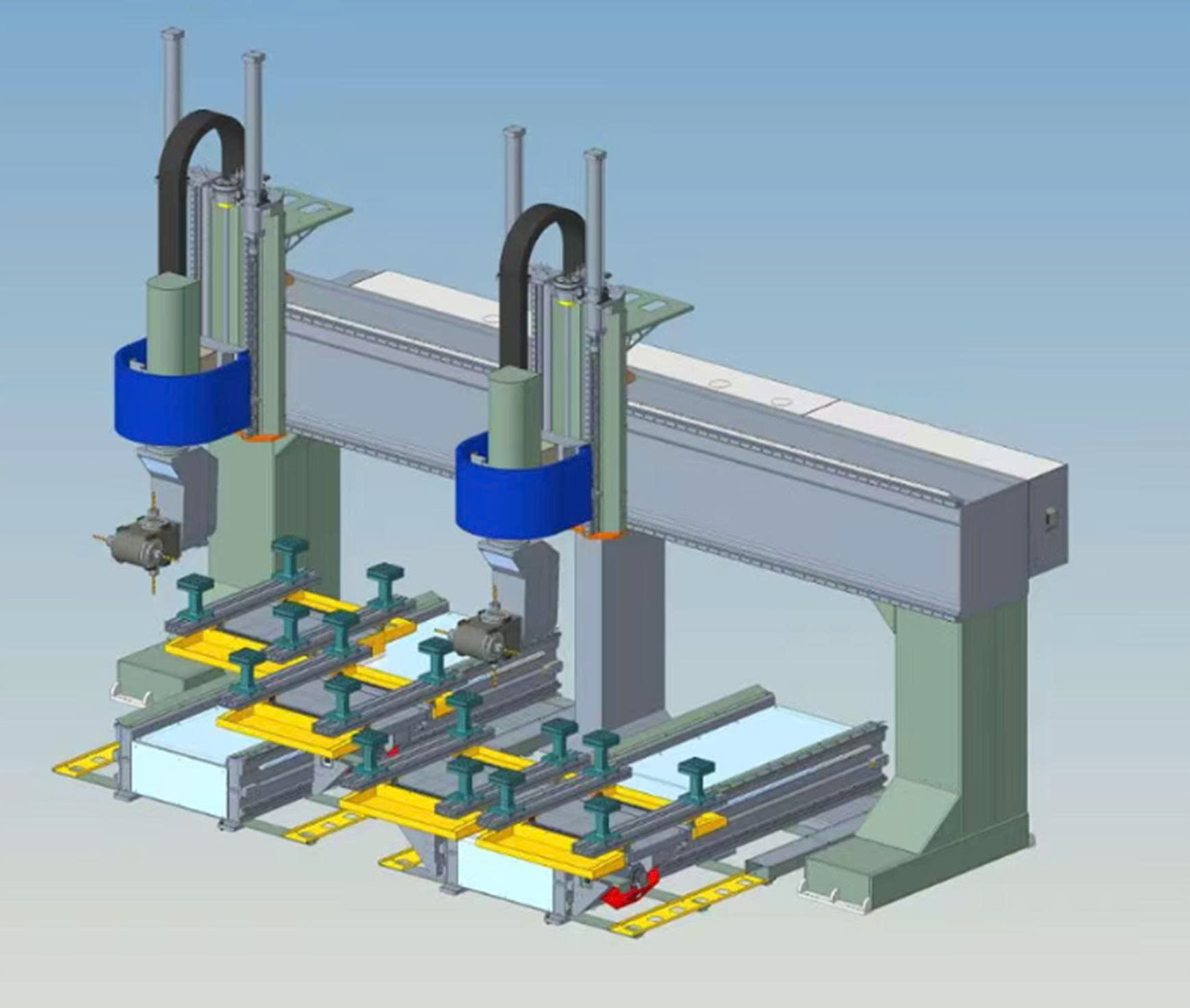

🆕 NEW PRODUCT ANNOUNCEMENT – 5-AXIS CNC MACHINE CHANG FENG CF-MASTERT3CU-28

🔧 BRAND: CHANG FENG

🌏 ORIGIN: CHINA

📌 MODEL: CF-MASTERT3CU-28

🔍 VERSION: 5-AXIS – MULTIFUNCTIONAL – HIGH PRECISION – PERFORMANCE OPTIMIZED

💡 KEY TECHNICAL SPECIFICATIONS

-

Worktable size: 1200mm × 1500mm

-

Number of worktables: 2 independent tables (simultaneous loading/unloading, fast operation)

-

Distance between gantries: 3000mm

Axis transmission system:

Rapid movement speed:

Axis travel:

-

X Axis: 3600mm

-

Y/U Axis: 2300mm

-

Z Axis: 1250mm

Rotary axis:

Electrical & Mechanical Specifications:

-

Working voltage: 380V – 3 Phase – 50Hz

-

Installed power: 48KW

-

Installation dimensions: 5400 × 4050 × 3800mm

-

Machine weight: ~7 tons

-

Electrical cabinet size: 1200 × 600 × 1800mm

-

Air pressure: 6 bar

-

Operating environment: 5°C – 40°C / Humidity: 30–95%

⚙️ PREMIUM HARDWARE CONFIGURATION

🔲 CNC Control System – OSAI (Italy)

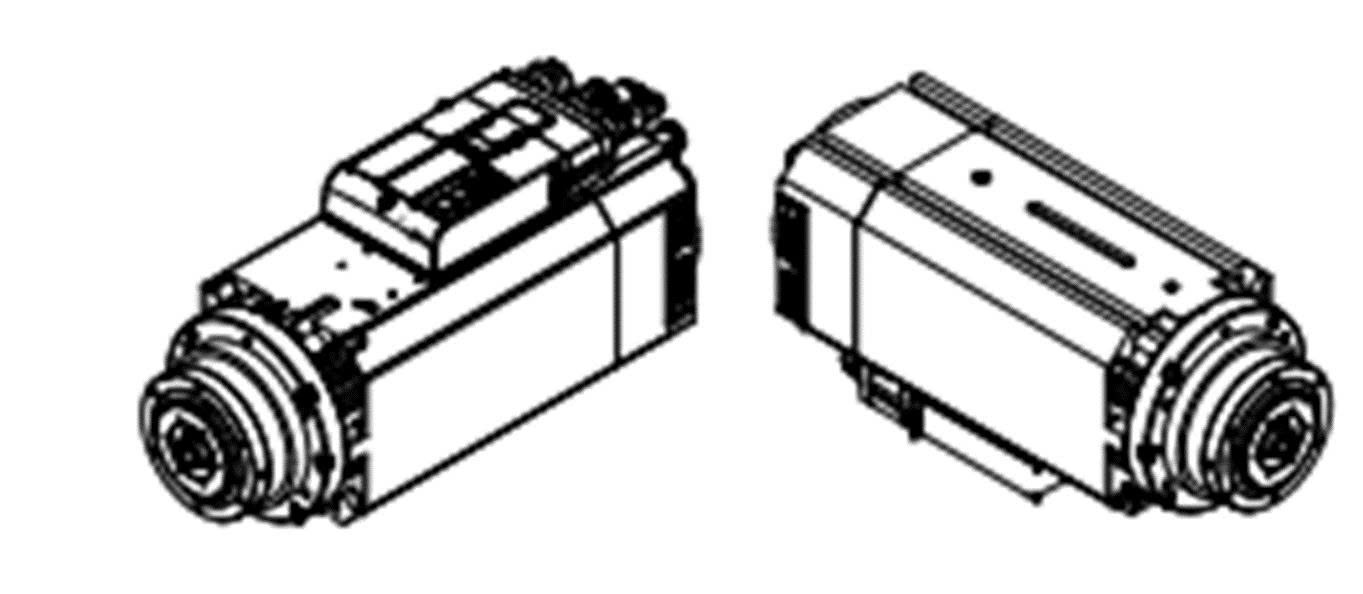

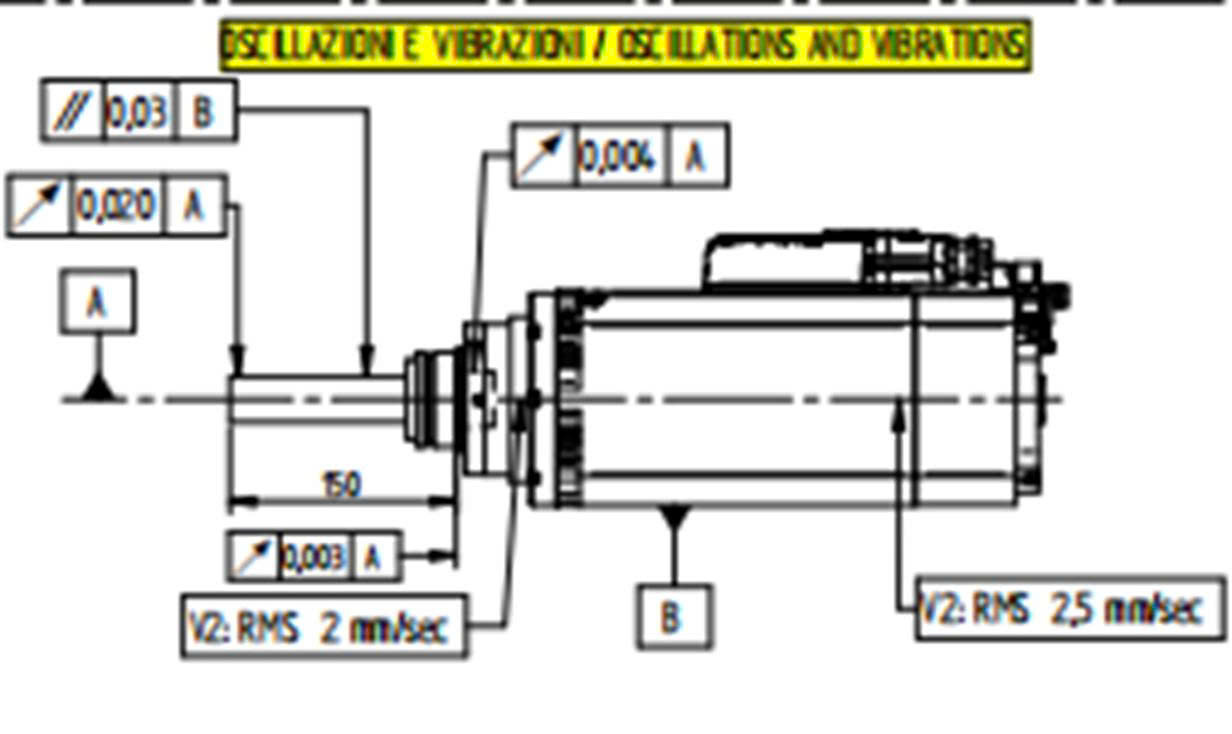

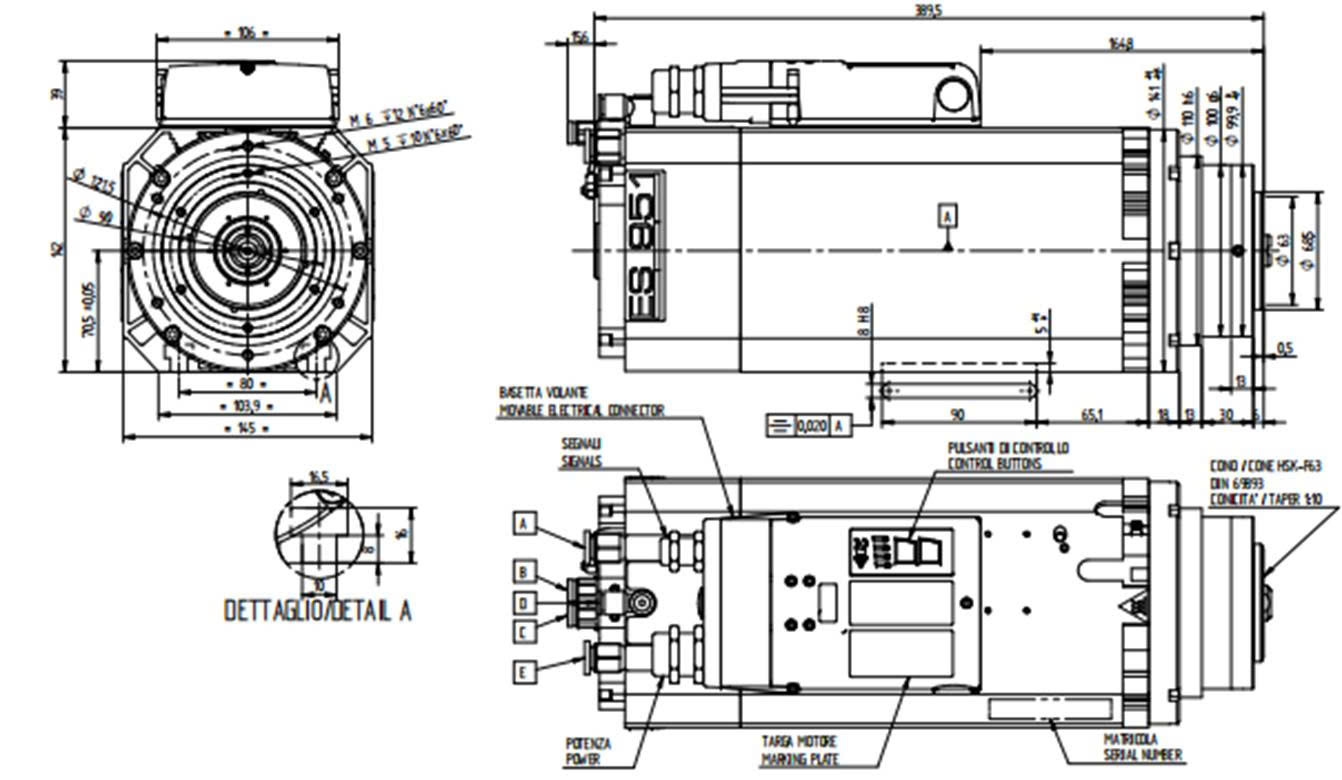

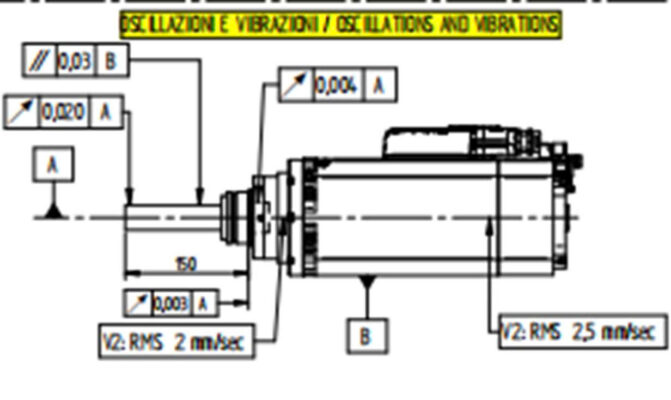

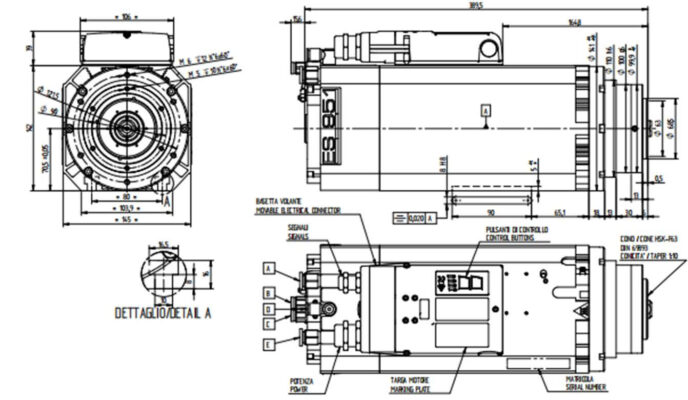

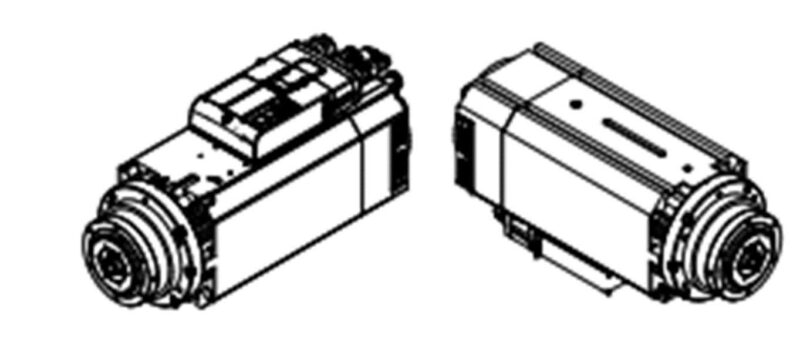

🌀 Main Spindle – HSD (Taiwan)

🌀 Main Spindles – GMT (Taiwan)

🧰 Auto Tool Changer – CHANG FENG

💻 Control Computer – ThinkStation P368

-

CPU: Intel Core i5-12500

-

RAM: 8GB DDR4 / SSD: 256GB

-

OS: Licensed Windows 11 Home

-

PSU: 300W with dual cooling fans

⚡ Servo System – YASKAWA (Japan)

-

Brushless motors, high speed, maintenance-free

-

Auto position memory on power-off

🔌 Inverter – VEICHUAN (China)

🛢️ Lubrication System – PROTON (China)

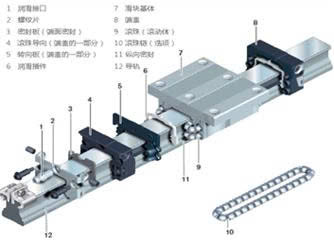

🧭 Linear Guide & Ball Screw – HIWIN (Taiwan)

-

4-way load, self-aligning, auto lubrication

-

Precision ground ball screws, preloaded

💨 Vacuum Pump – ORLEBA (Taiwan)

🔧 Pneumatic Components – AirTac (Taiwan)

⚙️ Electrical System – SCHNEIDER (France)

-

High-quality switches, relays, circuit breakers

-

Durable and safe components

🔄 Rotary Axes – SUMITOMO (Japan)

-

A & C Axes: Dual-servo control, precision drive

-

Cycloid reducer: shock-resistant, low backlash

-

Supports precise interpolation and position control

III. 🧩 WORKING COMPONENTS

-

Worktables: 2 (independent operation)

-

Vacuum beams: 6 (3 per table)

-

Clamping cylinders: 12

-

Vacuum cups: 12

-

Highly flexible for processing complex workpieces

IV. 🧠 PROFESSIONAL SOFTWARE

🔧 NX – Post-Processing CAM Software

🧠 ALPHA – Advanced 5-Axis Simulation Software

-

3D simulation of the entire machine, fixtures, and toolpaths

-

Collision detection prior to machining

-

OVERPASS module avoids collisions, optimizes paths

-

Enhances productivity and ensures machining safety

📦 Additional Features:

-

Standard process libraries: Drilling, Milling, Sawing, Tenoning, Boring…

-

Tool library graphic management

-

Assign product and part codes to each project

-

Axis travel limit checking

-

Custom machine configuration

-

Programmable code formatting (header/footer)

🎯 APPLICATIONS

✔️ High-end woodworking

✔️ Engineering plastics, composites

✔️ Mold parts, precision mechanical components

✔️ Complex 3D surface machining

VIDEO VẬN HÀNH MÁY:

📞 CONTACT INFORMATION

👨🔧Contact us now for free consultation and attractive offers!

☎️Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG