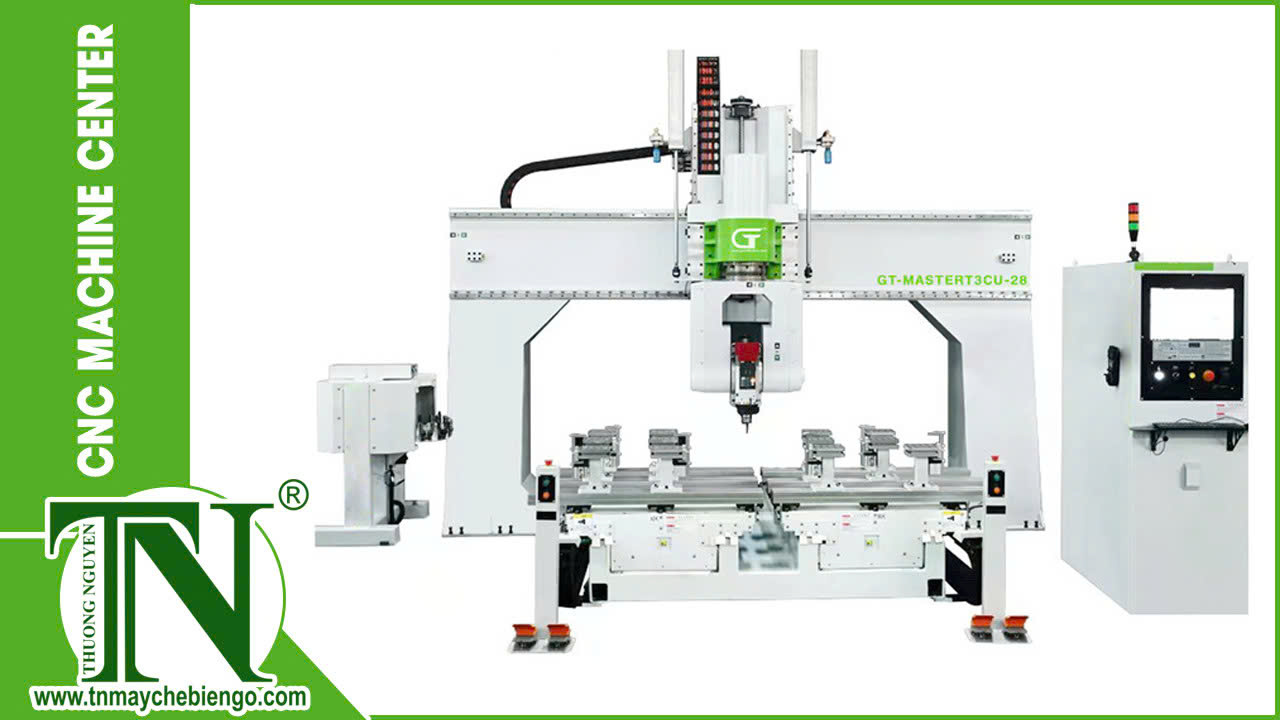

🆕 NEW PRODUCT ANNOUNCEMENT

🔧 FULLY AUTOMATIC TOOL-CHANGING 5-AXIS CNC MACHINE

📌 BRAND: CHANG FENG – ORIGIN: CHINA 📌 MODEL: CF-C3ATC1-28

💡 MAIN TECHNICAL SPECIFICATIONS

🔩 Drive System:

⚡ Maximum Travel Speed:

🔁 Rotary Axes:

⚙️ Mechanical Parameters:

Operating voltage : 380V – 3 phase – 50Hz

Installed power : 28KW

Vacuum pipe : 16mm – Input cable : 10mm²

Machine weight : approx. 6 tons

🛠️ Pneumatic System:

Air pressure: 6 bar

Central pneumatic system equipped with filters, pressure regulators, lubricators, and minimum pressure controllers

🌡️ Installation & Operating Environment:

Must be installed on solid concrete flooring (not on soft soil)

Operating temperature: 5℃ – 40℃ , 24-hour average not exceeding 35℃

Relative humidity: 30% – 95%

⚙️ HIGHLIGHTED HARDWARE CONFIGURATION

🔩 Spindle:

Power: 12KW

Max speed: 24,000 RPM

Spindle taper: HSK63F

⚡ High-Performance Servo System:

Absolute encoder system – no need for homing after restart

Position memory and high safety

Brushless high-speed motors – maintenance-free, high precision & performance

🔌 Inverter:

💻 Control System:

🛢️ Lubrication:

🧭 Linear Guides & Ball Screws:

Ultra-high rigidity, heavy load-bearing linear guides

4-way load design , self-aligning

Ground ball screws with preload , minimizing backlash, increasing stiffness and precision

🔌 Electrical Components:

🧰 Tool Magazine:

Disc-type automatic tool changer

Capacity: 10 tool positions

Tool holders: 10 ER40-HSK63F holders

💨 Vacuum Pump:

🔄 Rotary Head:

A & C axes driven independently by dual servo motors

Combined with high-precision bearing assembly and cycloidal reducer

Ensures continuous high-precision positioning , high durability, impact resistance, and low-backlash motion

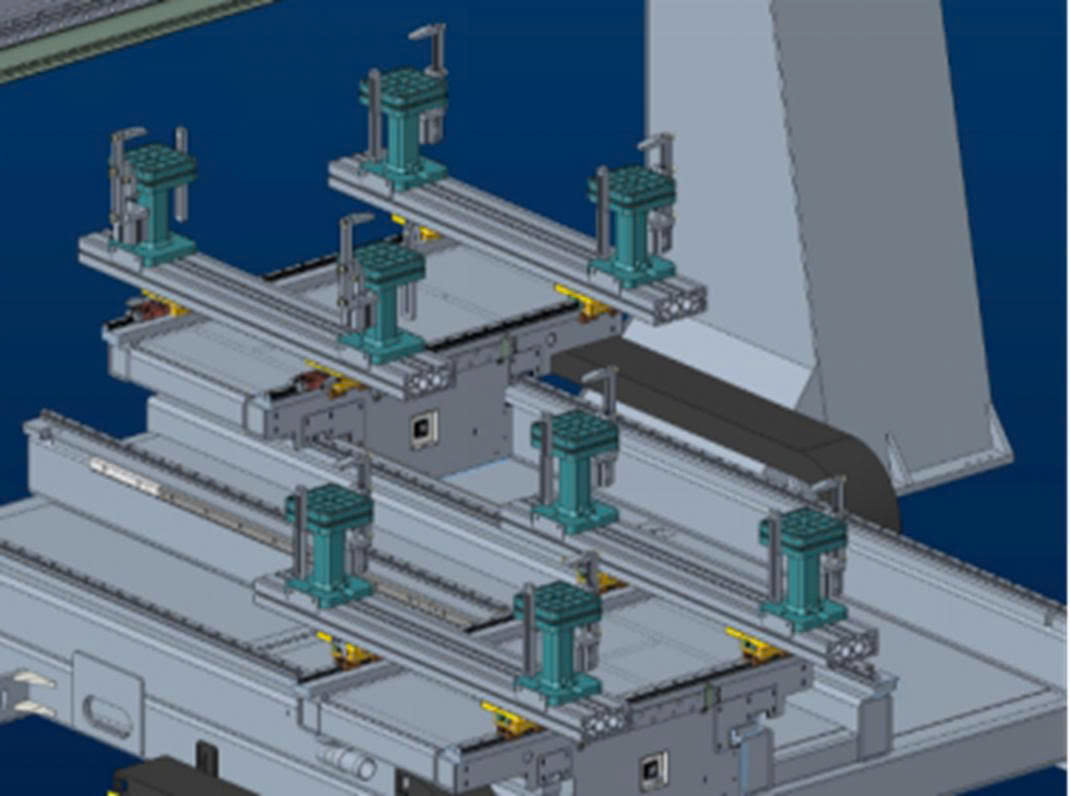

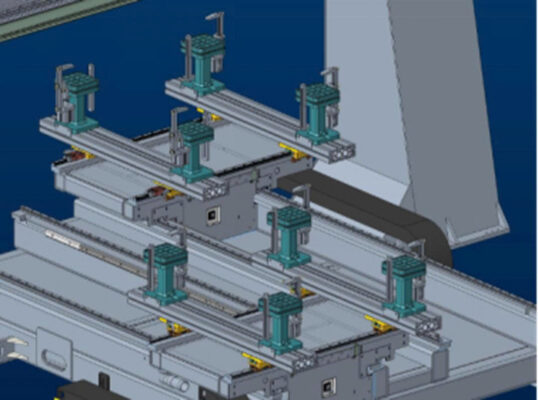

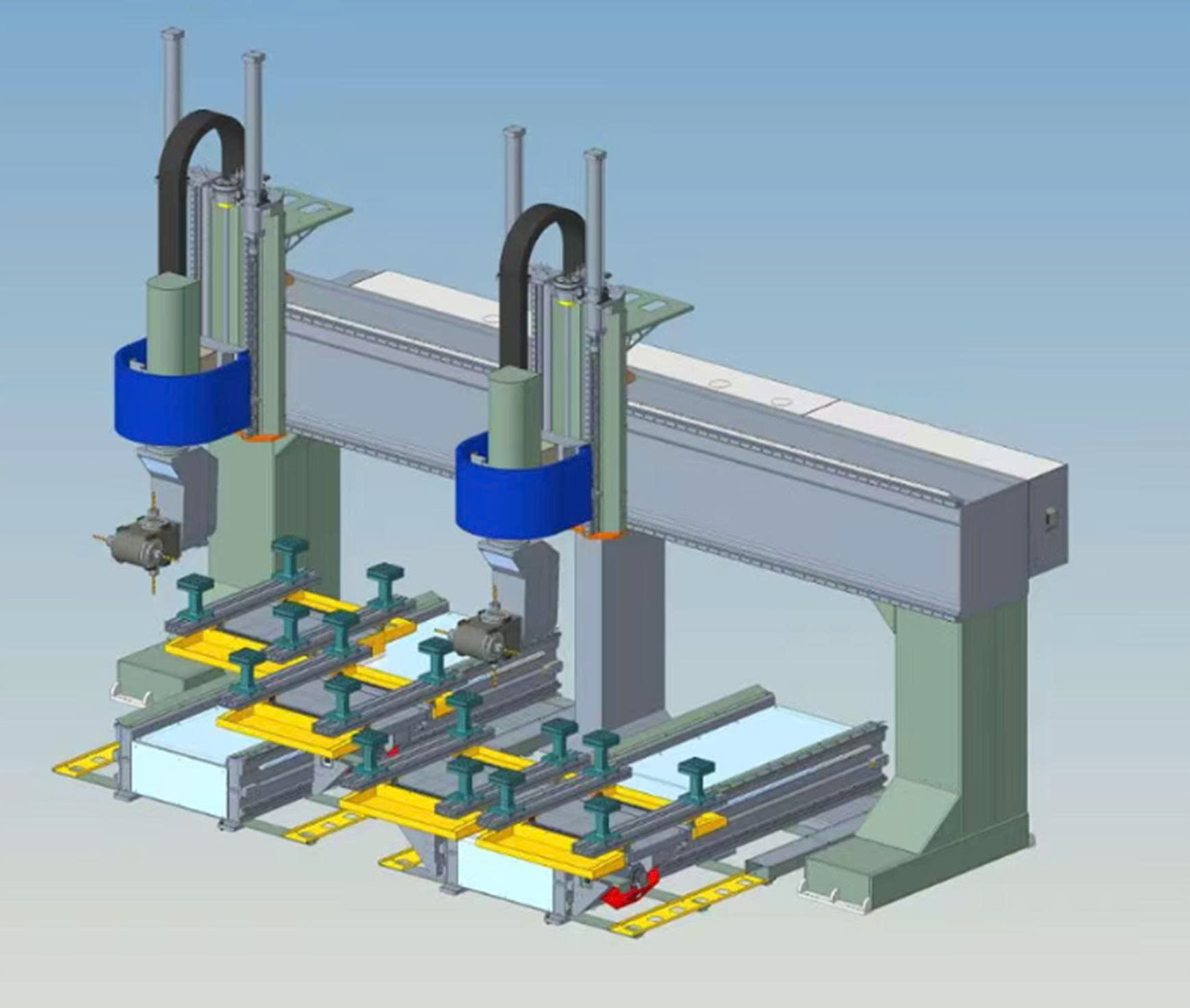

III. 🧩 MACHINING COMPONENTS

Component

Quantity

Vacuum beams (per table)

2×2 (dual table)

Pneumatic clamps

8

Vacuum cups

8

IV. 🧠 ADVANCED SOFTWARE CONFIGURATION

🧩 Post-Processing CAM Software:

🔍 Advanced Simulation – Official ALPHA Software :

3D simulation of the full machine : machine body, fixtures, tools, and parts

Detects collisions and programming errors before execution

OVERBRIDGE module : Automatically bridges collision paths with optimal rerouting

🧰 Standard Processing Modules:

Prebuilt modules for: Drilling – Milling – Cutting – Boring – Tenoning – Sawing

Tool library management : graphical interface, easy tool referencing

Project management : assign product names, part numbers, and details per project

Travel limit checking : warns if axis travel exceeds during G-code execution

Customizable machine configuration : define headers, footers, tool change codes, and more

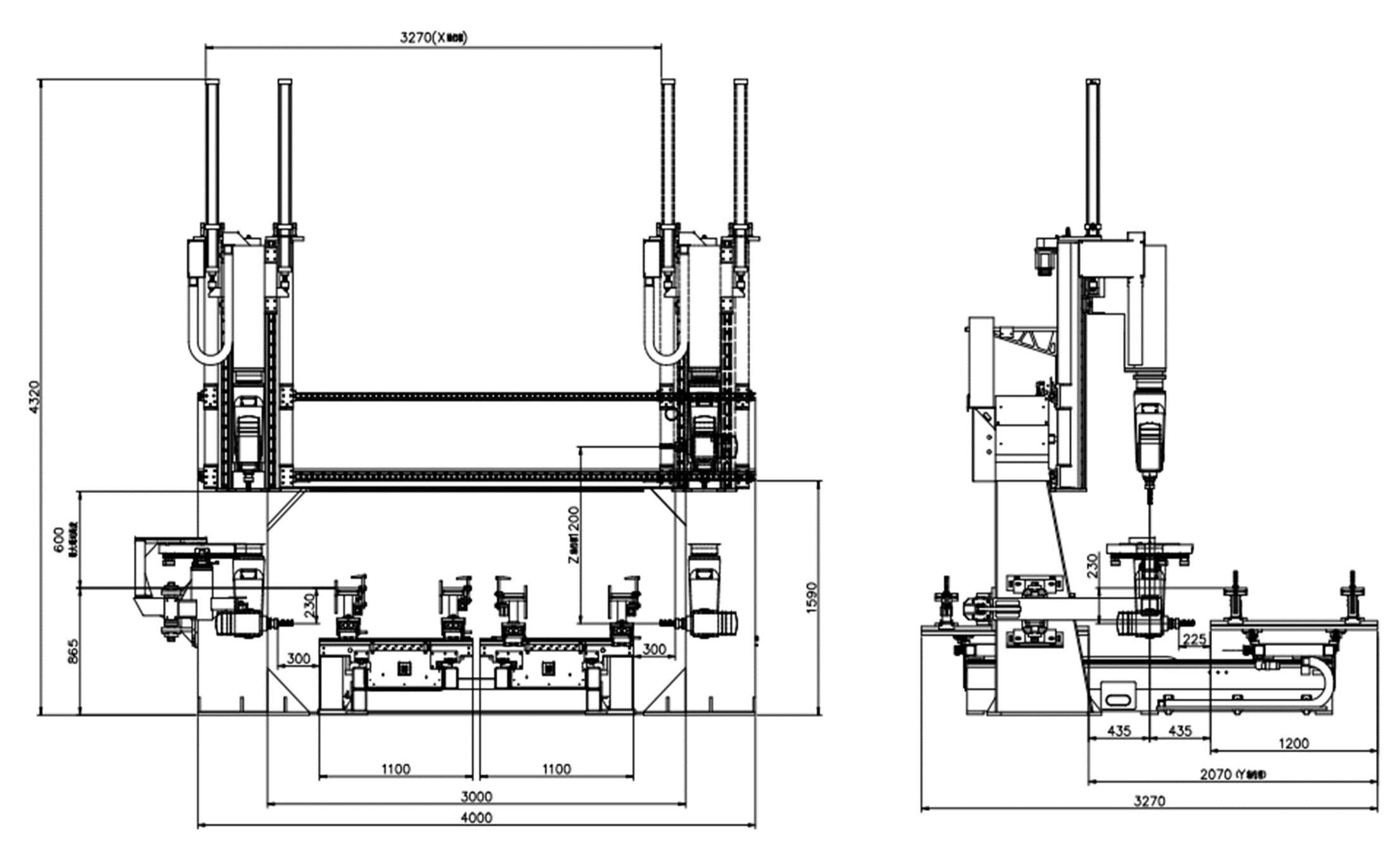

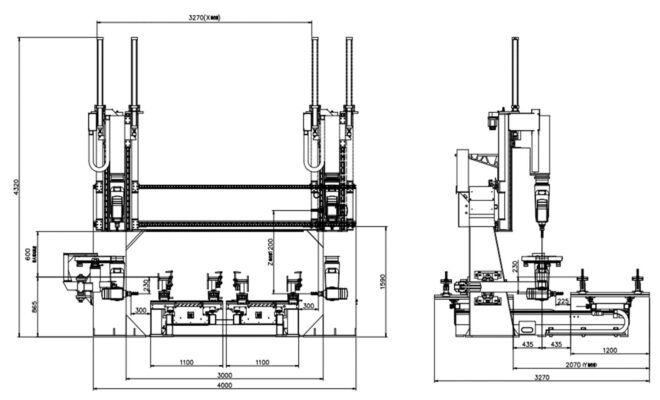

📐 V. INSTALLATION LAYOUT

(Please contact us for detailed floor plan drawings suitable for your workshop space )

🎯 APPLICATIONS

✔️ High-end furniture and woodwork manufacturing technical plastics, composite materials mold parts and mechanical components 3D surface machining and curved contours

📞 CONTACT INFORMATION

👨🔧Contact us now for free consultation attractive offers !

☎️Hotline : 0902 98 58 98

🌐 Website : https://maychebiengotn.com/

📩 Email : [email protected]

📲 Fanpage : https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG