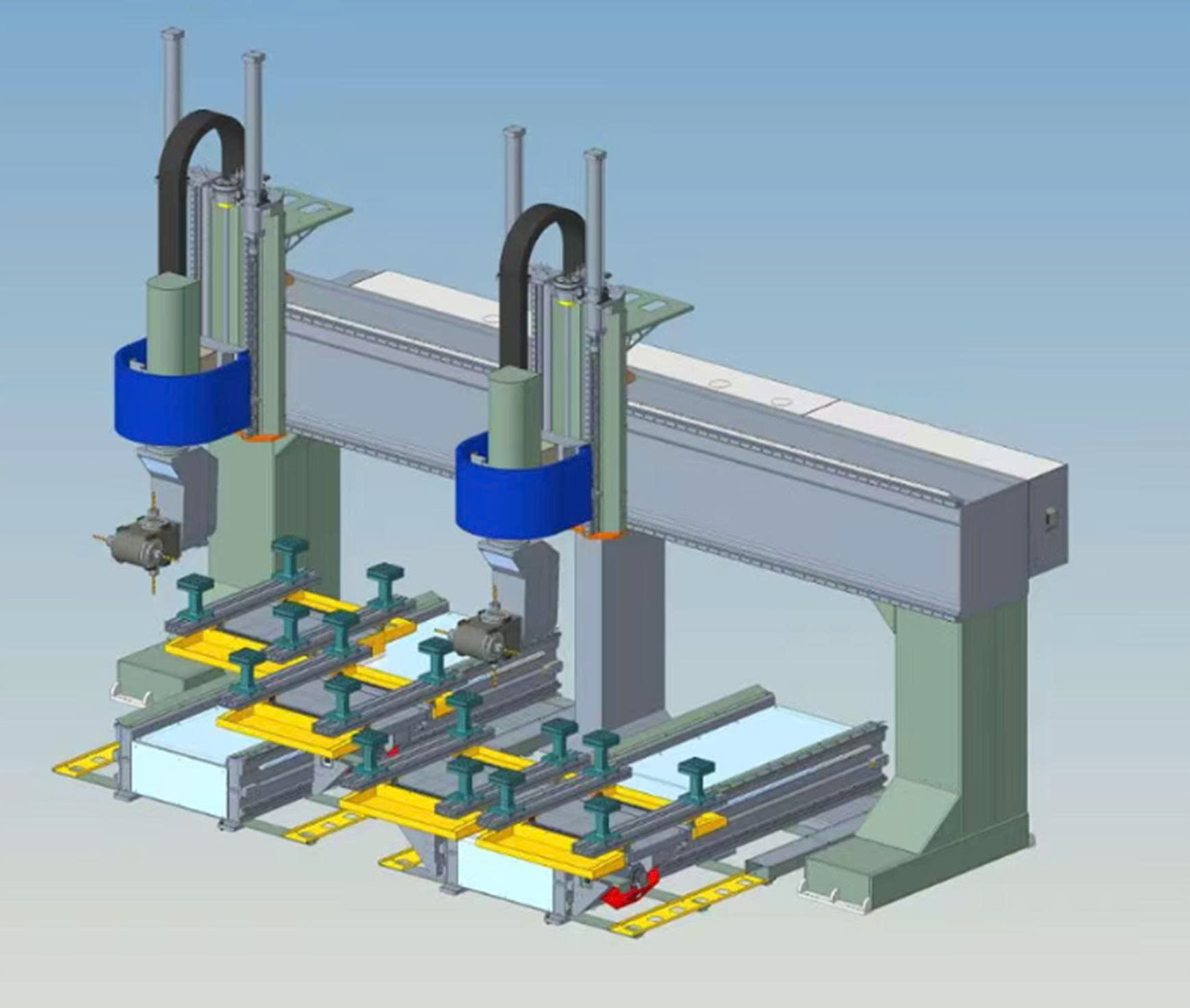

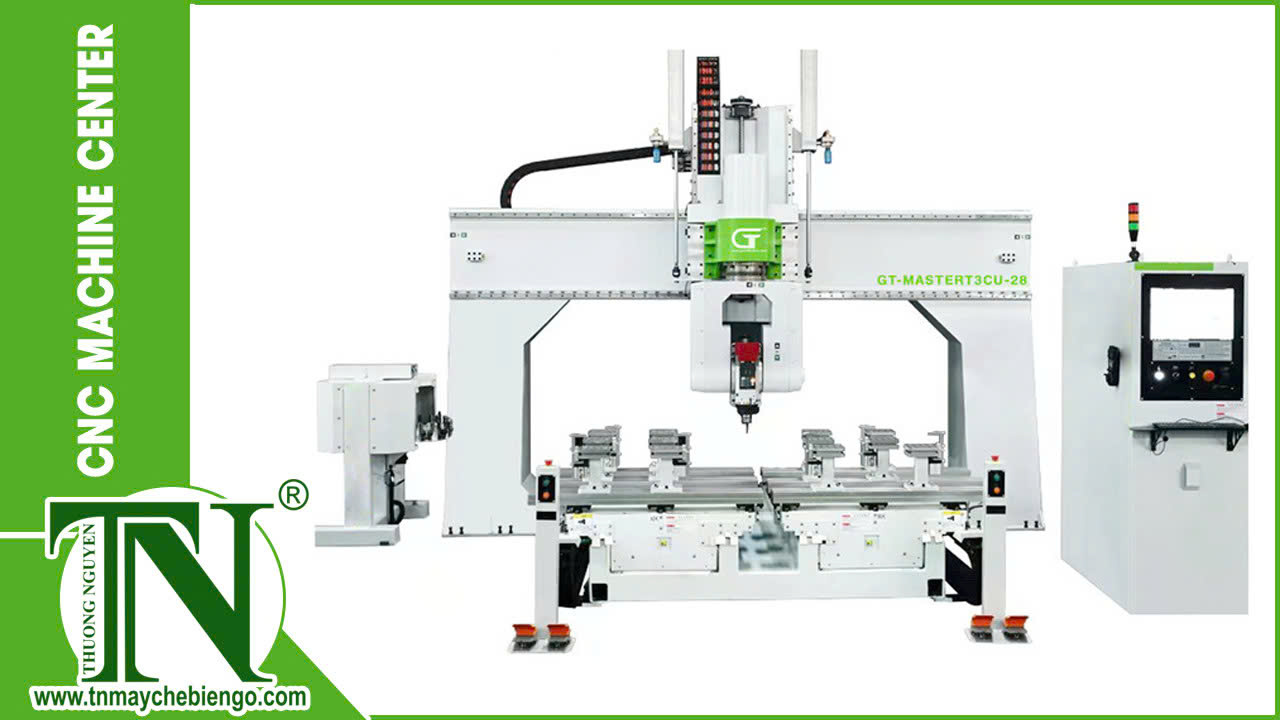

🛠️ INTRODUCING THE CHANG FENG CF-MASTERT4-28 5-AXIS CNC MACHINE – 100% BRAND NEW

✅ STANDARD VERSION – HIGH PERFORMANCE – EXCEPTIONAL VALUE

Brand: CHANG FENG – Origin: China

Model: CF-MASTERT4-28

🔧 MAIN SPECIFICATIONS

| Item |

Technical Specifications |

| Working table size |

1200mm × 1500mm × 2 tables |

| Distance between columns |

3000mm |

| X/Y/U axis transmission |

Imported precision ground rack & pinion |

| Z axis transmission |

Precision ball screw |

| Rapid traverse speed |

X/Y/Z/U: 60m/min |

| X axis stroke |

3600mm |

| Y/U axis stroke |

2300mm |

| Z axis stroke |

1250mm |

| A axis (rotation) |

Continuous rotation |

| C axis |

±380° |

| Operating voltage |

380V – 3 Phase – 50Hz |

| Installed power |

48KW |

| Machine dimensions (L×W×H) |

5400 × 4050 × 3800 mm |

| Machine weight |

Approx. 7 tons |

⚙️ HARDWARE CONFIGURATION

🔲 CNC System: OSAI (Italy)

-

Interpolation cycle: 2ms

-

Supports: 8 interpolating axes / up to 16 (8 via Mechatrolink)

-

Dual independent control channels

-

Automatic state memory during power outage

🌀 Spindles: GMT (Taiwan)

-

4 independent spindles – each 9.6kW

-

GMN (Germany) ceramic bearings

-

Max speed: 24,000 RPM

-

Pneumatic cooling – supports saw blades, straight bits, profiling bits

-

Tool holders: 4×ER40

🖥️ Control Computer: Changfeng (China)

⚡ Servo System: YASKAWA (Japan)

-

Brushless, high-speed, maintenance-free

-

Auto position memory after shutdown

🌀 Inverter: VEICHUAN (China)

🛢️ Automatic Lubrication: PROTON (China)

🧭 Guide Rails & Ball Screws: HIWIN (Taiwan)

💨 Vacuum & Pneumatic System

🔌 Electrical & Cabling

-

Electrical components: Schneider (France)

-

Oil-resistant, flame-retardant, flexible cables

-

Durable drag chains

🔄 Gear Reducers & Rotary Axes: Sumitomo (Japan)

🔩 OPERATING COMPONENTS

🧠 INCLUDED SOFTWARE

🔧 NX Post-processing Software

📐 ALPHA Advanced 5-Axis Simulation Software

-

Full 3D simulation of machine and tooling

-

Collision detection before real machining

-

“OVERPASS” auto-collision avoidance module

📦 Additional Features:

-

Modular process library: Drilling, milling, mortising, sawing, carving, countersinking…

-

Graphical tool management

-

Project & product code tracking

-

Travel limit check per axis

-

Easy creation of virtual machines per user specs

-

Customizable program headers/footers

🧳 APPLICATIONS

✔ High-end wood machining

✔ Composite & engineering plastic processing

✔ Mold & industrial parts manufacturing

✔ High-precision 5-axis machining

📞 CONTACT INFORMATION

👨🔧Contact us now for free consultation and attractive offers!

☎️Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG