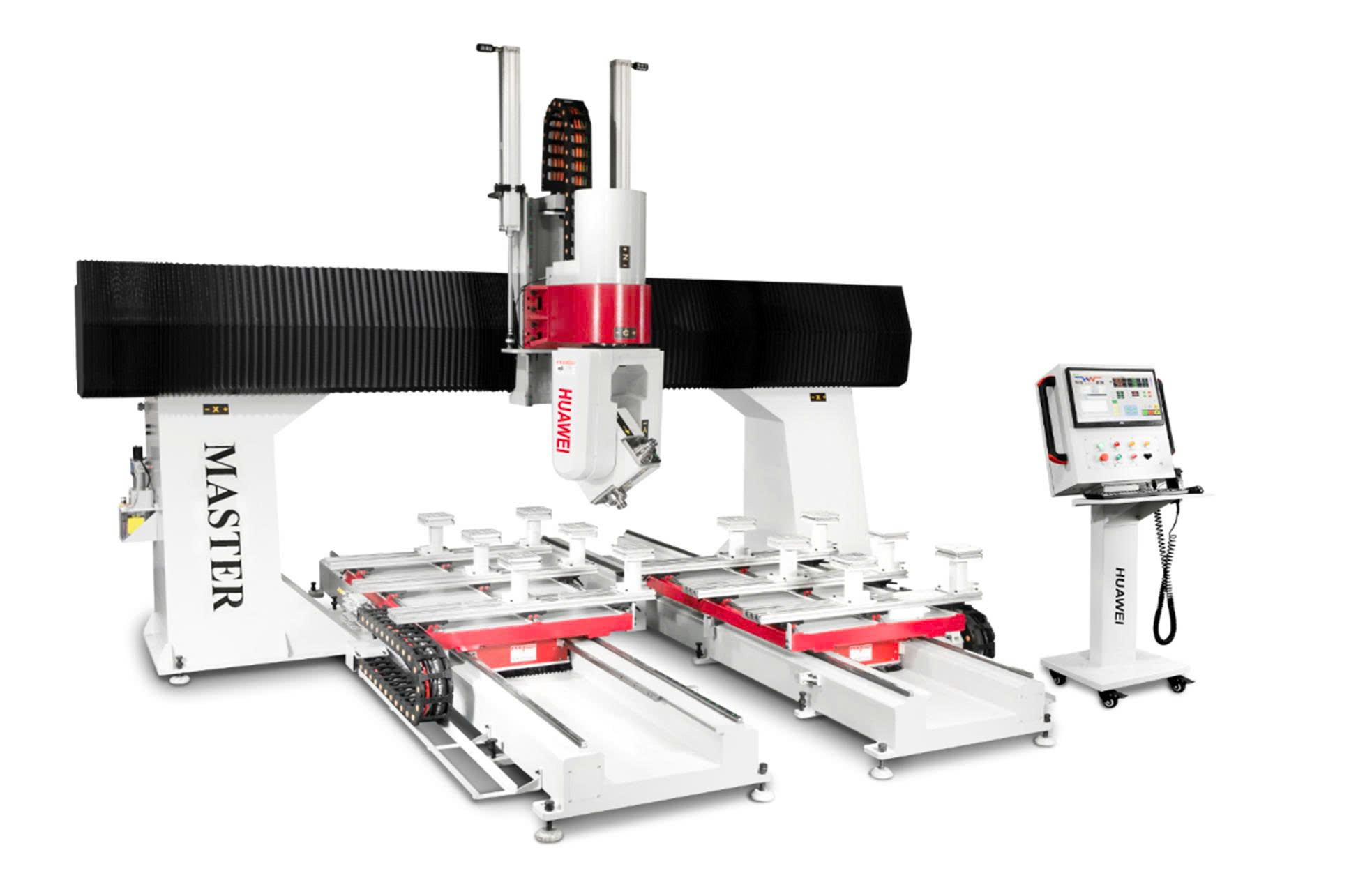

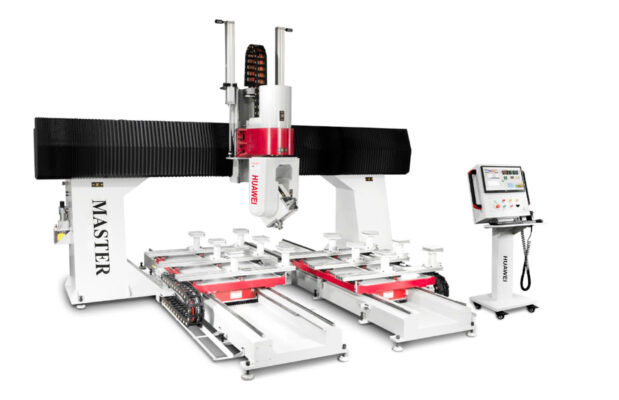

🔧 INTRODUCING THE 5-AXIS CNC MACHINE – HUAWEI HW-ARTIFICER-TC4

💯 Optimized Performance – High Precision – Smart Technology Integration – 100% Chinese Technology

🏭 GENERAL OVERVIEW:

-

Brand: HUAWEI

-

Origin: China

-

Model: HW-ARTIFICER-TC4

-

Total Installed Power: 34.5 kW

-

Power Supply: AC 380V / 50Hz / 3 Phase

-

Required Air Pressure: 6 bar

-

Machine Weight: Approx. 6500 kg

-

Machine Dimensions (L×W×H): 4710 × 3300 × 3400 mm (excluding control box and electrical cabinet)

⚙️ KEY TECHNICAL SPECIFICATIONS:

-

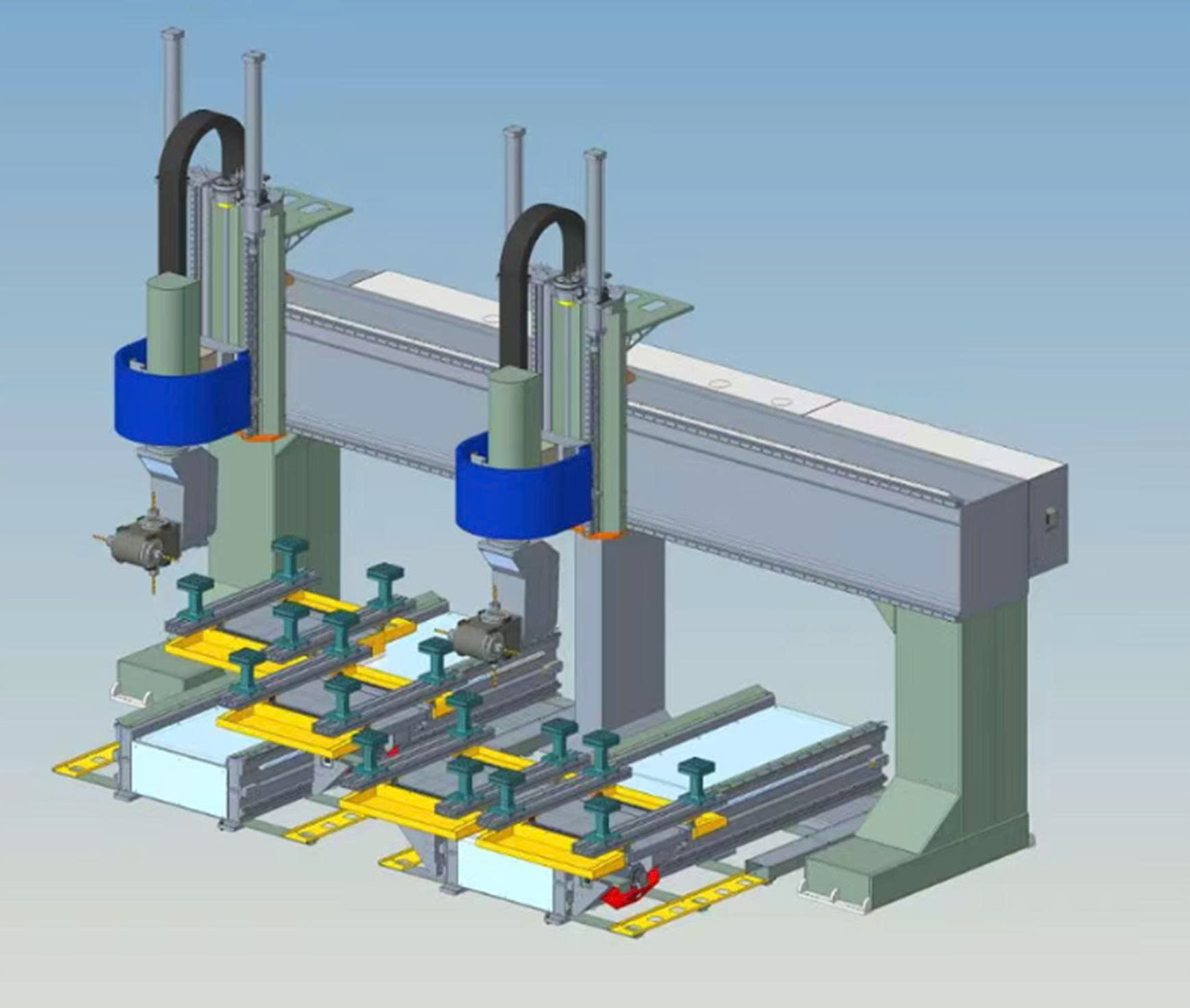

Vacuum Table Size: 1200 × 1600 mm × 2

-

Number of Vacuum Tables: 2 units

-

Distance Between Columns: 3010 mm

🛠 Axis Travel:

-

X Axis: 3450 mm (Max speed: 70 m/min)

-

Y Axis: 2630 mm (Max speed: 70 m/min)

-

Z Axis: 850 mm (Max speed: 50 m/min)

-

C Axis (Rotary Head): ±400°

-

A Axis (Rotary Head): Continuous Rotation

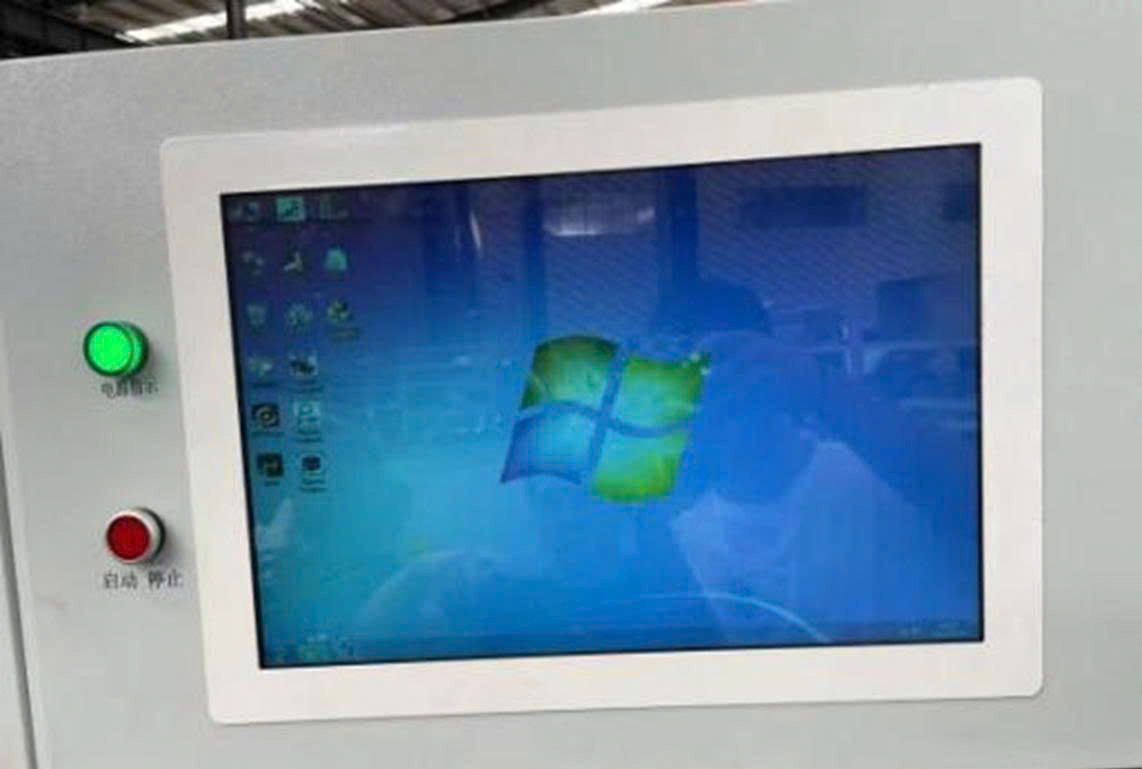

🖥️ DISPLAY & CONTROL SYSTEM:

-

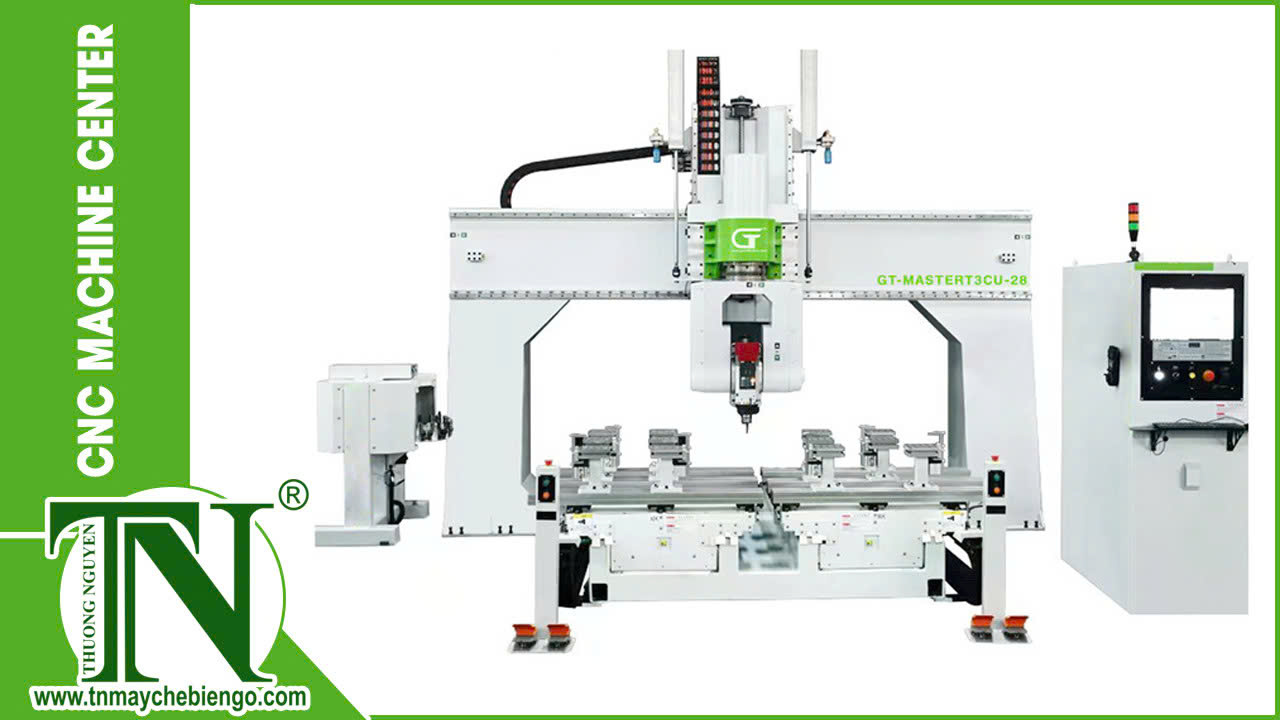

19-inch Industrial Touchscreen, All-in-One Embedded System

-

Compact design, integrates both controller and display for easier use

-

Low power consumption, smart heat dissipation, quiet operation

-

Durable material: shockproof, dustproof, and waterproof

-

High-performance processor & large memory for fast, accurate data processing

🔩 SPINDLE SYSTEM:

-

4 Independent Spindles with Dual Arm Design

-

Supports 4 types of tools or saws simultaneously

-

Tool/saw change time: under 1 second

-

Spindle motor power: 9.6 kW (Shenyi)

-

Equipped with high-precision automatic tool setter, saving manual effort and increasing machining accuracy

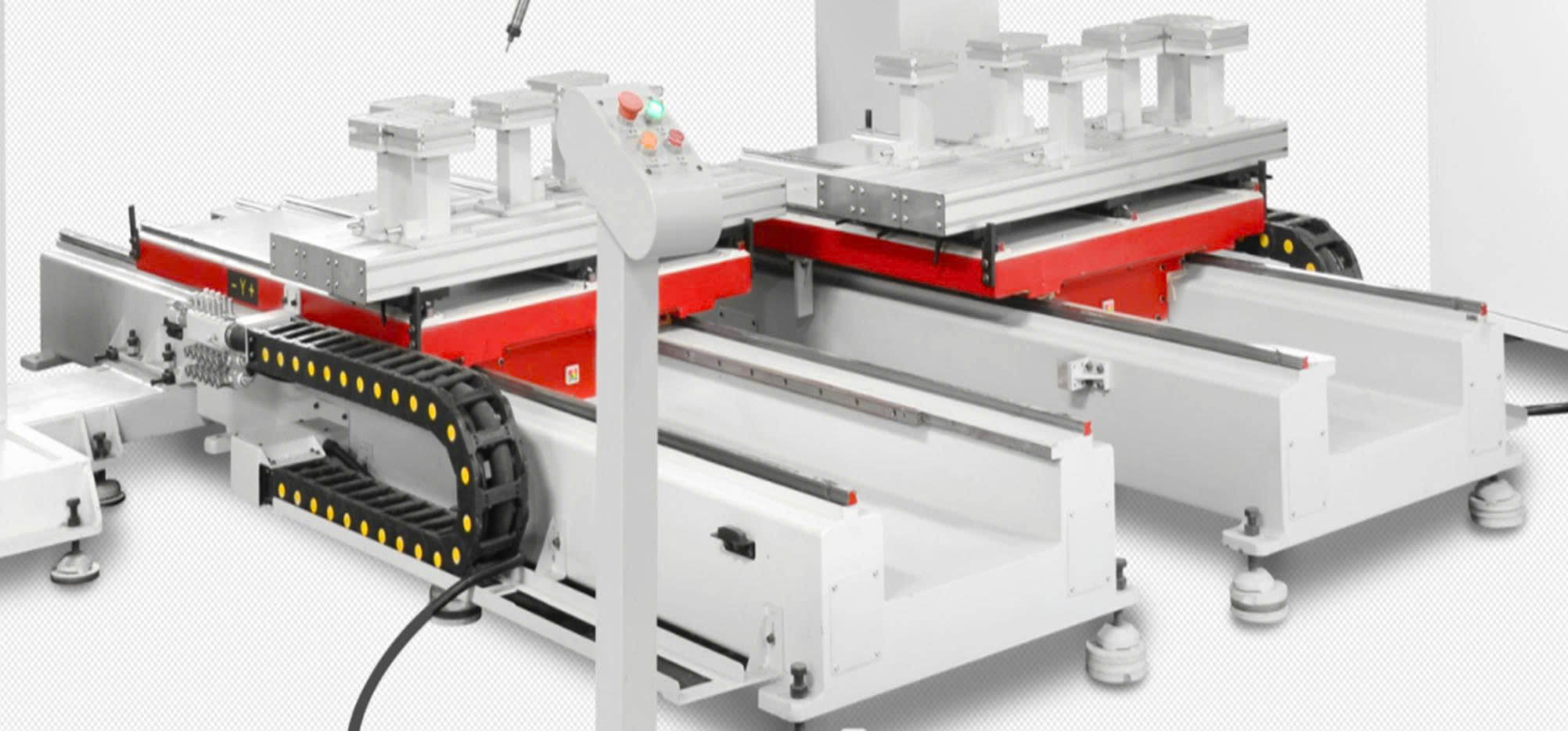

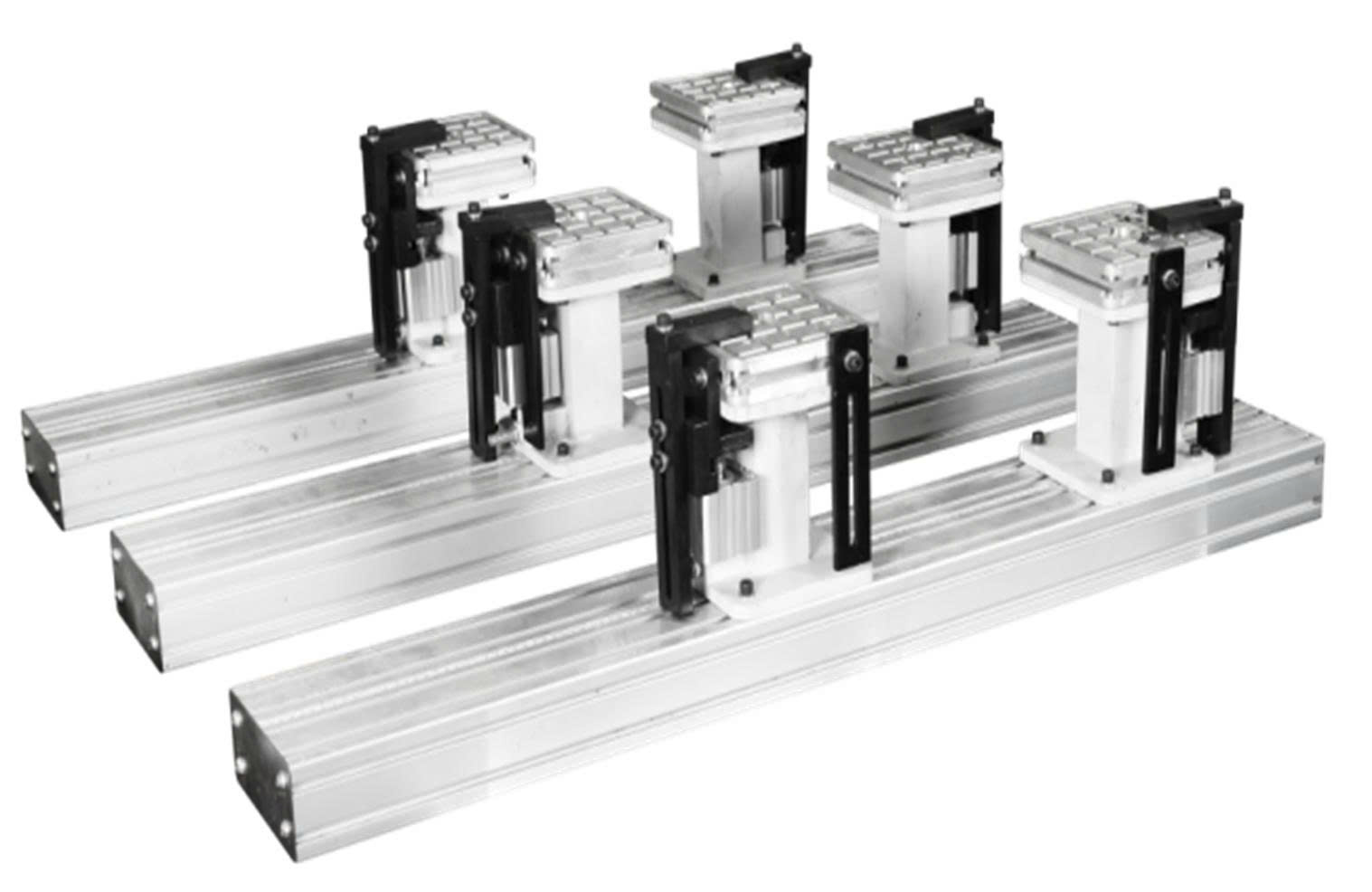

🧲 HIGHLY FLEXIBLE VACUUM TABLE SYSTEM:

-

Linear guide rails from Hiwin (Taiwan)

-

Dual independent tables for continuous load/unload workflow

-

Synchronous processing mode: both tables can be combined into one for large workpieces

-

Table Components:

⚡ SERVO MOTORS – HUICHUAN (CHINA):

-

X Axis: 2.0 kW

-

Y Axis: 1.5 kW

-

Z Axis: 2.0 kW

-

C Axis: 1.5 kW

-

A Axis: 1.0 kW

🏆 Outstanding Features of Huichuan Servo System:

-

High precision: Closed-loop control of position, speed, and torque

-

High speed: Rated speed generally reaches 3000–7000 RPM

-

Strong overload capacity: Handles up to 3.5× rated torque

-

Excellent stability: Smooth operation at both low and high speeds, significantly reduces heat and noise

-

Fast response: Dynamic acceleration/deceleration in just tens of milliseconds

✅ OUTSTANDING ADVANTAGES:

-

Accurately machines complex and high-precision parts

-

Ultra-fast tool/saw changes improve efficiency

-

Dual vacuum tables allow for continuous and flexible production

-

Advanced industrial hardware and smart control integration

-

Built to withstand harsh environments – dustproof, waterproof, shockproof

-

Easy to operate, maintain, and ensures long-term stable performance

📞 CONTACT US FOR CONSULTATION & QUOTATION:

Looking for a high-performance, smart, and cost-effective 5-axis CNC solution?

💬 Reach out today for:

-

Expert technical consultation

-

Live simulation and software demo

-

Best pricing on the market

👨🔧Contact us now for free consultation and attractive offers!

☎️Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG