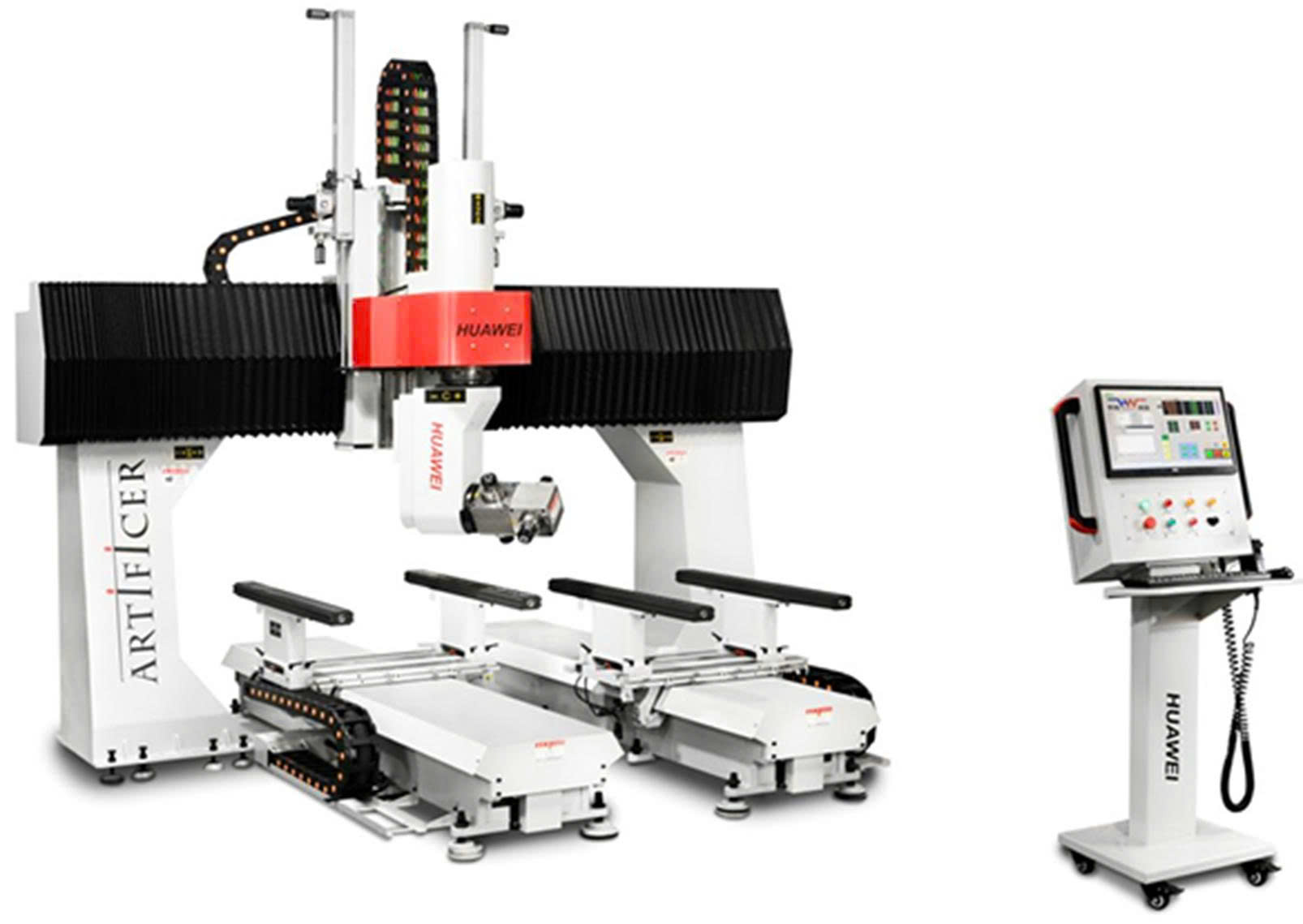

🔧 INTRODUCING THE 5-AXIS CNC MACHINE – HUAWEI HW-ARTIFICER-TC2+TC2

💯 Outstanding Performance – Absolute Precision – Advanced Technology from China

🏭 GENERAL INFORMATION:

-

Brand: HUAWEI

-

Origin: China

-

Model: HW-ARTIFICER-TC2+TC2

-

Installed Power Capacity: 34.5 kW

-

Power Supply: AC 380V / 50Hz / 3 Phase

-

Required Air Pressure: 6 bar

-

Machine Weight: Approx. 6000 kg

-

Machine Dimensions (L×W×H): 3650 × 3350 × 3600 mm (excluding control cabinet and operator panel)

⚙️ KEY TECHNICAL SPECIFICATIONS:

🛠 Axis Travel:

-

X Axis: 2650 mm (Speed: 70 m/min)

-

Y Axis: 2200 mm (Speed: 70 m/min)

-

Z Axis: 850 mm (Speed: 50 m/min)

-

C Axis (Rotary Head): ±4000°

-

A Axis (Rotary Head): Continuous rotation

🧠 CNC SYSTEM & SOFTWARE:

🔩 SPINDLE SYSTEM:

-

Diagonal dual-motor layout for high efficiency

-

2 dual-output manual tool change spindles

-

Motor Power: 7.5 kW (Shenyi)

-

Equipped with 4 blades or saws simultaneously

-

Ultra-fast tool change time: Less than 1 second for improved production efficiency

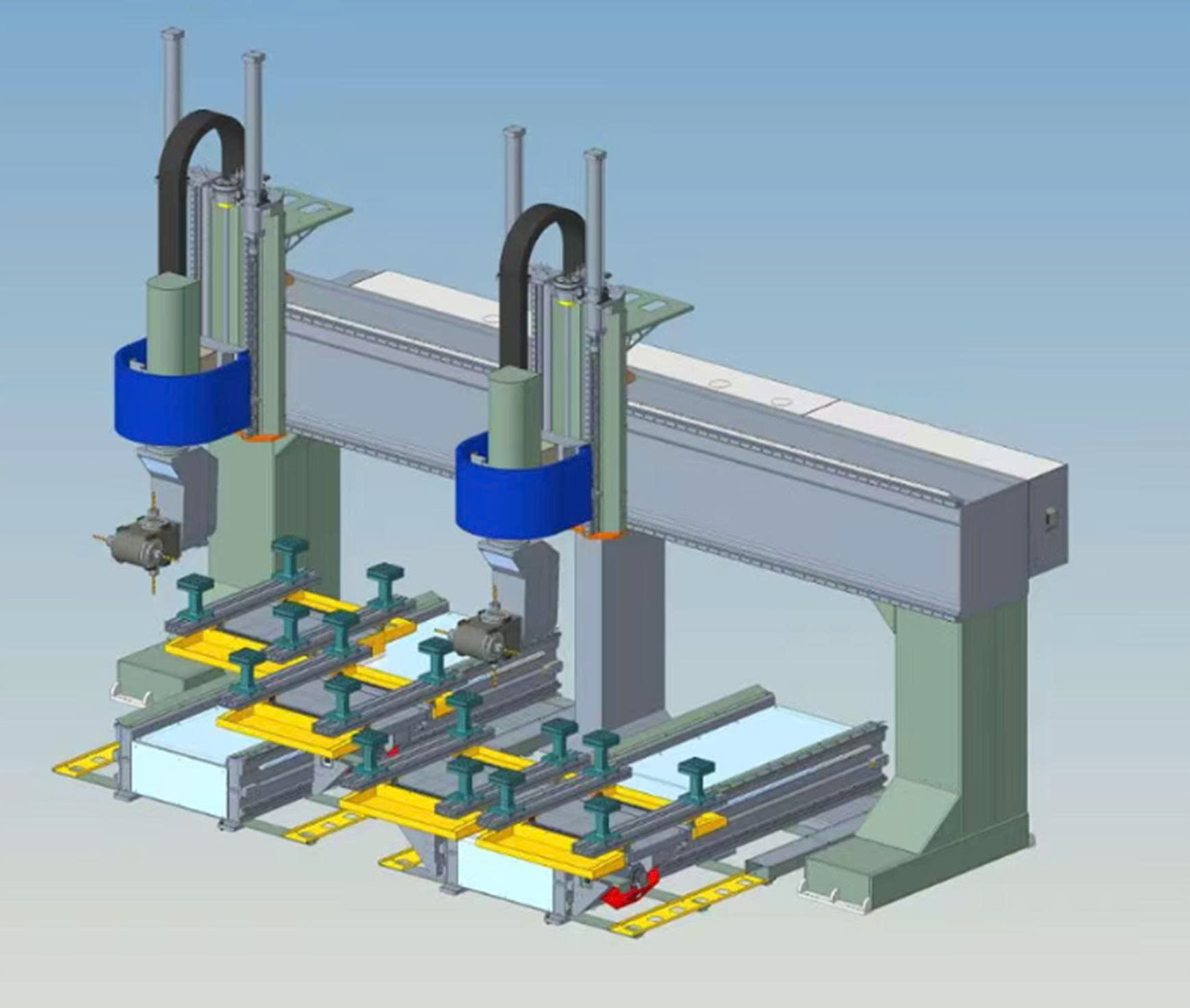

🧲 HIGHLY FLEXIBLE VACUUM TABLES:

-

Dual table structure with linear guide rails from Hiwin (Taiwan)

-

CNC-synchronized mode: Tables can be merged for large workpieces

-

Independent loading/unloading: While one table is machining, the other can be used for material handling

-

Simultaneous movement: Both tables can move together to process larger parts

💨 VACUUM SYSTEM:

🌬️ COOLING & ELECTRICAL SYSTEM:

-

Air conditioning in control cabinet: Ensures stable operation, superior to traditional fan cooling

-

Automatic oil lubrication system for smoother axis operation

🔗 DRIVE SYSTEM & HIGH-QUALITY COMPONENTS:

-

Precision Linear Guide Rails: Hiwin (Taiwan)

-

X Axis: HGW30HC

-

Y Axis: HGW25HC

-

Z Axis: HGW30HC

-

Ball Screw Mechanism:

-

Pneumatic Components: AirTac (Taiwan)

-

AC Contactors: Schneider (France)

-

Limit Switches: Omron (Japan)

-

Cables: High-flex industrial grade

✅ KEY ADVANTAGES:

-

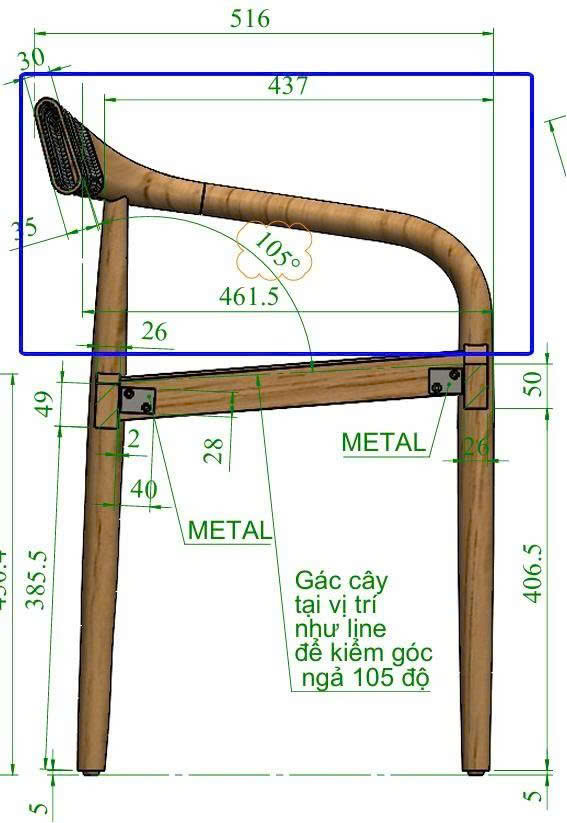

High-speed, flexible machining for complex and large-scale parts

-

User-friendly CNC interface with built-in simulation and anti-collision features

-

Rapid tool and saw changes, saving time in high-volume production

-

Dual working tables enhance workflow continuity

-

Rugged construction and premium components ensure long-term reliability

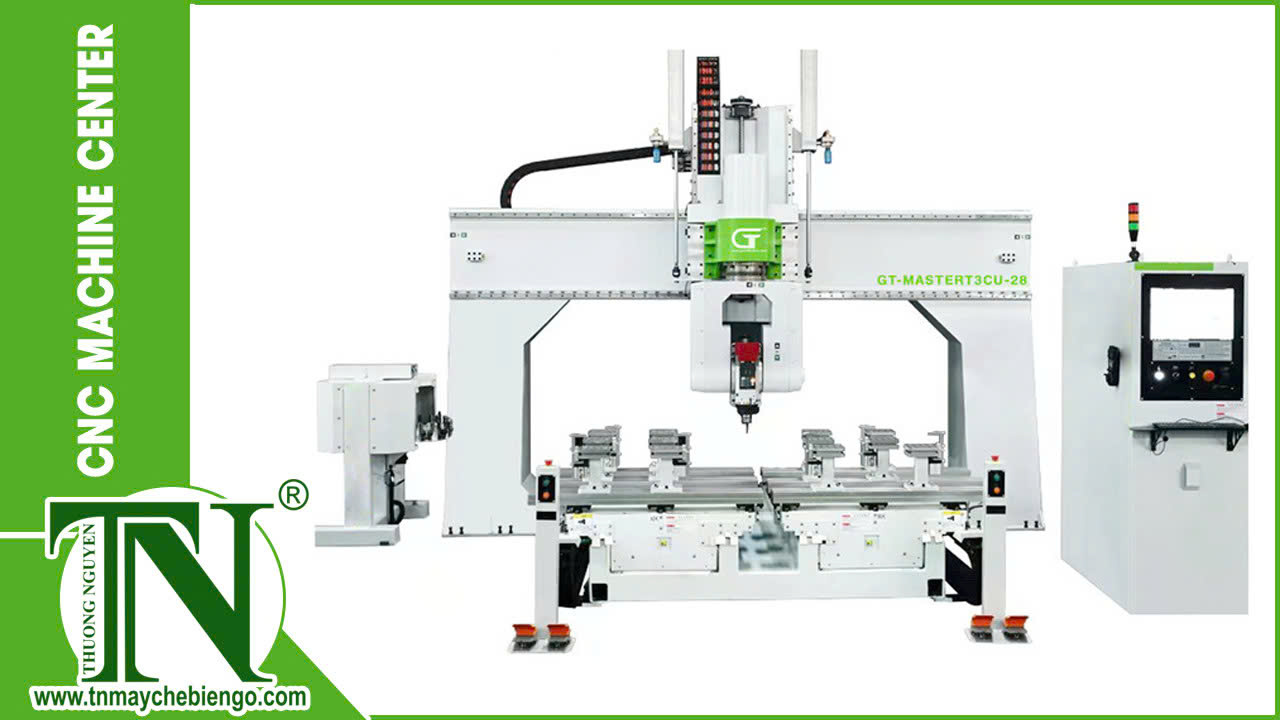

📞 CONTACT US FOR CONSULTATION & QUOTATION:

💬 Interested in the HUAWEI HW-ARTIFICER-TC2+TC2 5-Axis CNC Machine? Reach out now for technical support, competitive pricing, and live software demo.

👨🔧Contact us now for free consultation and attractive offers!

☎️Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG