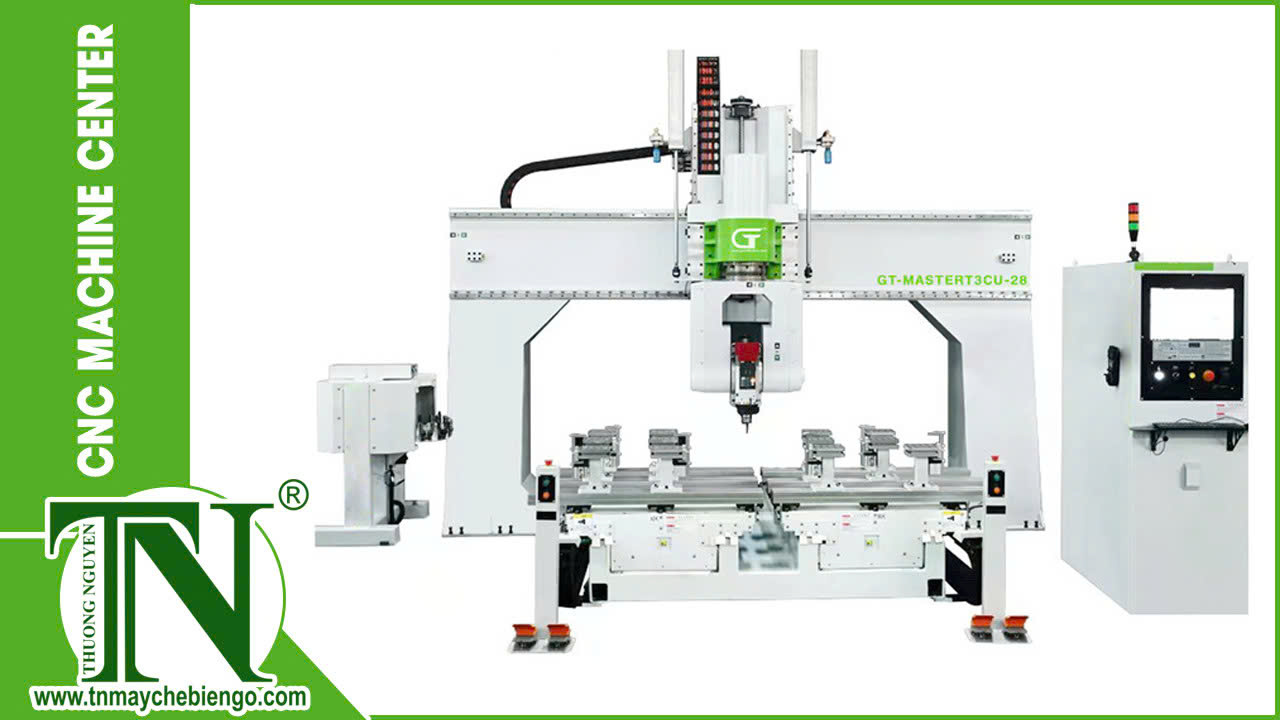

🎯 OFFICIAL PRODUCT ANNOUNCEMENT – FULLY AUTOMATED 5-AXIS CNC DOUBLE-HEAD MACHINE – CF-DOUBLET2-PT Brand: CHANG FENG | Origin: China Model: CF-DOUBLET2-PT | Power: 35KW | CNC System: OSAI OPENsmart

🔧 I. BASIC SPECIFICATIONS

Maximum axis travel speed :

Rotary Axis :

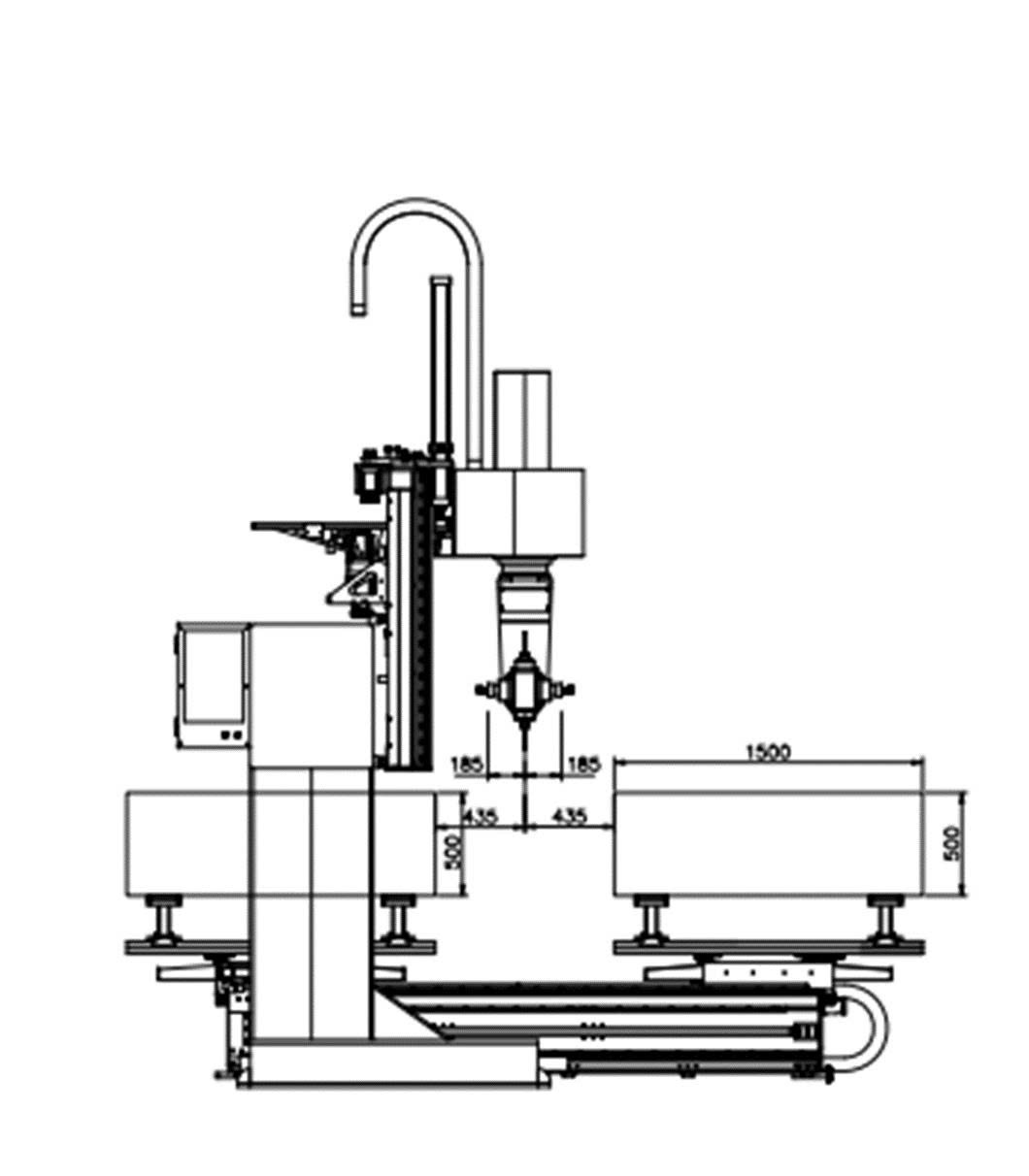

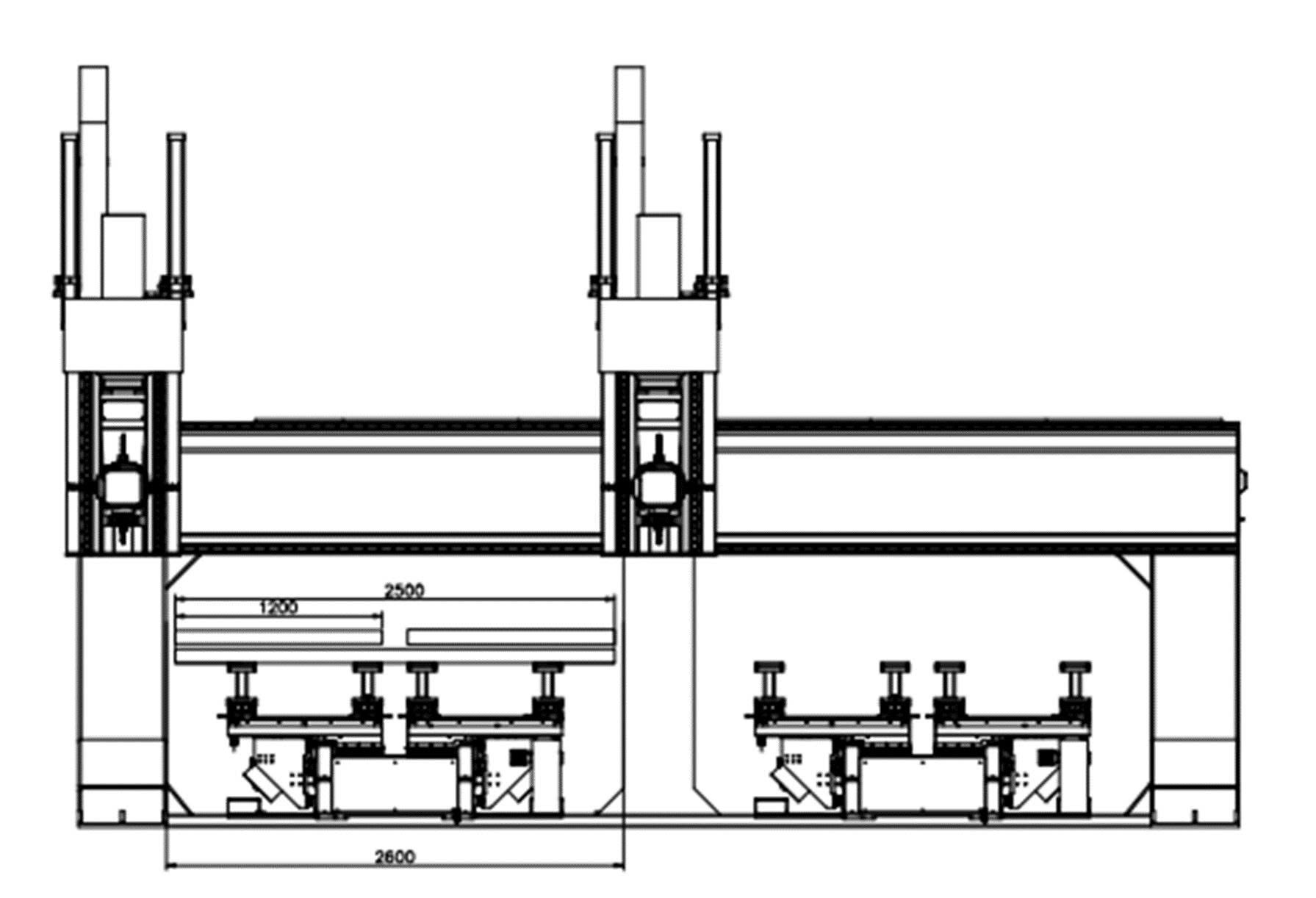

Machine dimensions (L×W×H) : 3615 × 3514 × 3845 mm

Power supply : 380V, 3-phase, 50Hz

Air pressure : 6 bar

Installed power : 35KW

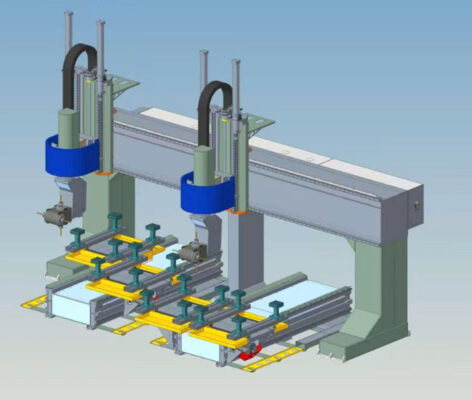

🧱 II. MACHINE STRUCTURE

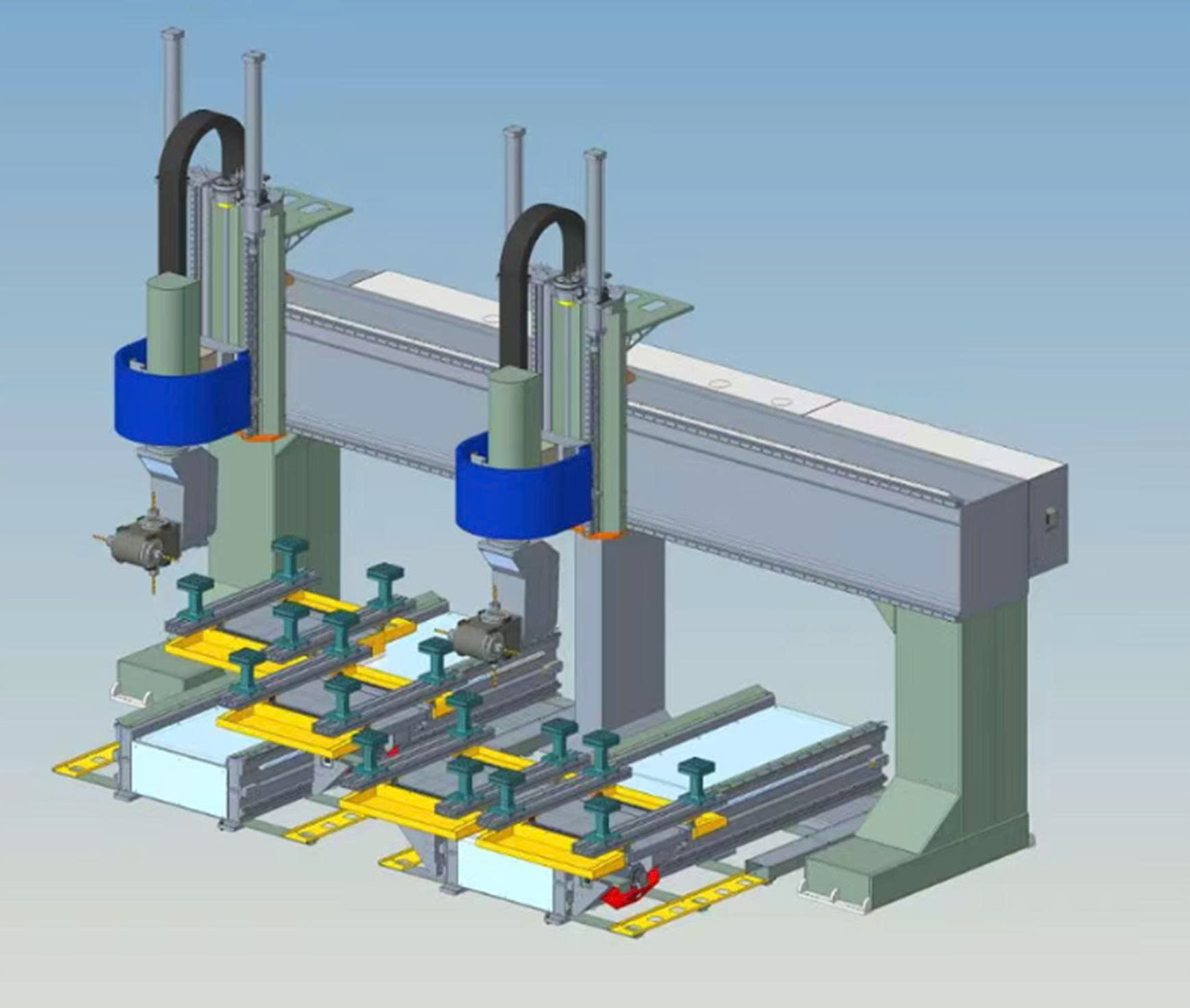

Integrated welded frame , gantry-style, offering excellent rigidity and long-term stability.

Square worktable design , strong load-bearing capability, ensures long-term machining precision.

Linear guide rail and ball screw drive , high stiffness and wear resistance.

Vertical Z-axis slide , combined with dual rotary head (A + C axis) for high flexibility.

🔩 III. MULTI-TASKING WORKING PLATFORM

Vacuum & pneumatic clamping system allows simultaneous multi-part processing:

High-efficiency multi-tasking operation with superb accuracy.

🛠 IV. SPINDLE CONFIGURATION

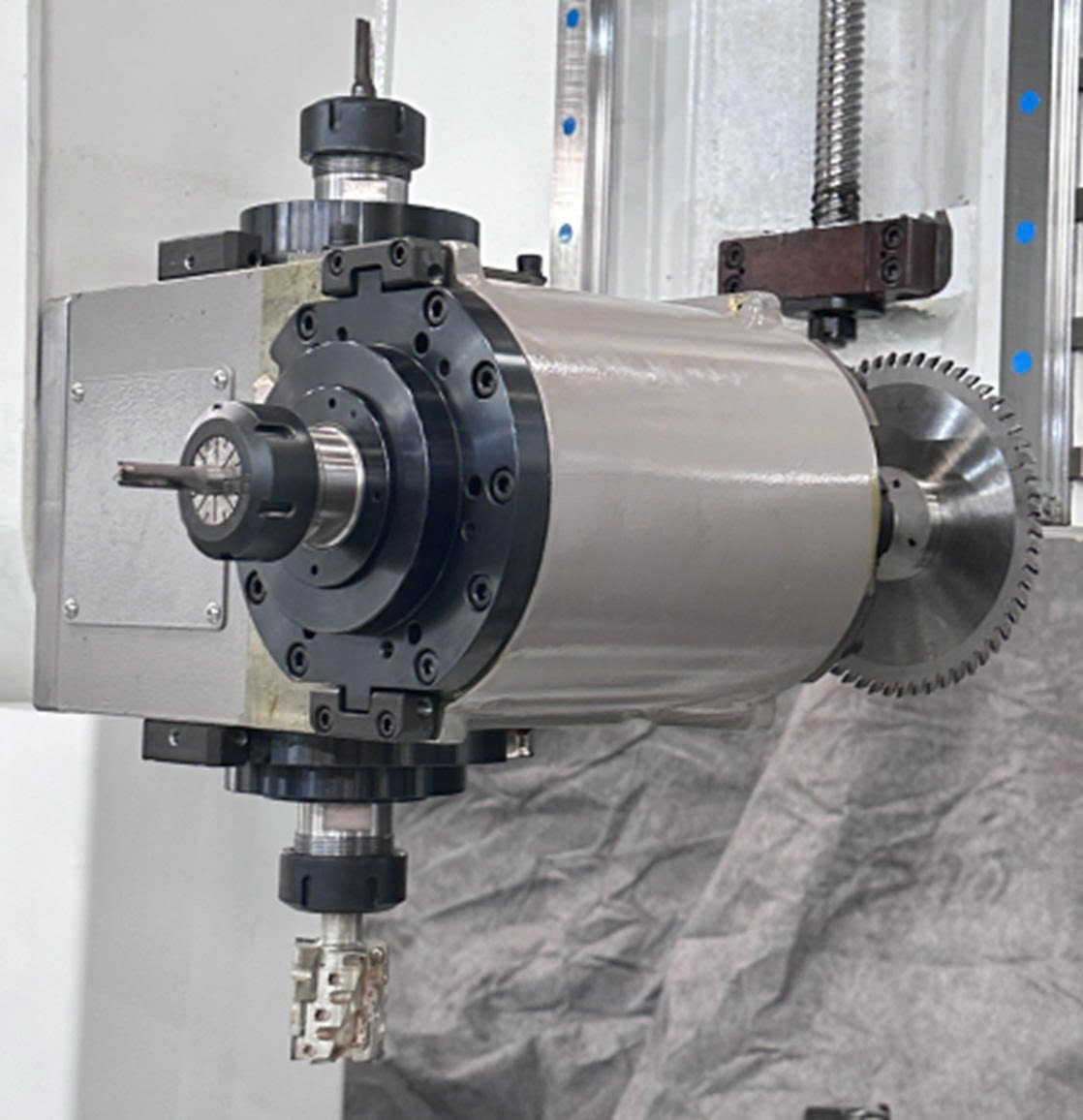

Two independent double-head processing units , totaling 4 high-speed electric spindles:

4× 7.5KW independent inverters

German GMN bearings : Smooth and durable performance

⚙ V. PREMIUM TRANSMISSION & DRIVE SYSTEM

X/Y/U axes with precision ground helical rack and pinion transmission , zero backlash

Z-axis uses high-grade ball screw , preloaded and anti-deflection

Four-way linear guideways for ultra-high rigidity

A/C axis use Sumitomo reducers (Japan)

Pneumatics by AIRTAC – Taiwan

High-speed, oil-resistant, flame-retardant cables

Electrical components : Schneider – France

🖥 VI. CNC SYSTEM & SOFTWARE

CNC System: OSAI OPENsmart (Italy) with user-friendly Windows interface

Workstation: ThinkStation P368, i5-12500 CPU, 8GB RAM, 256GB SSD

Compatible with official NX CAM post-processor and ALPHA simulation software

Key software functions include :

🔋 VII. SUPPORTING SYSTEMS

4× KVE160 5.5HP dry vacuum pumps (Shanggang Orleba – Taiwan)

Manual tool change (2 heads) , supports multiple tool types: straight bits, shaped cutters, saw blades,…

🚀 SUMMARY

📞 Contact us now for a free consultation and quote!

👨🔧Contact us now for free consultation attractive offers !

☎️Hotline : 0902 98 58 98

🌐 Website : https://maychebiengotn.com/

📩 Email : [email protected]

📲 Fanpage : https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG