✨ CHARACTERISTIC:

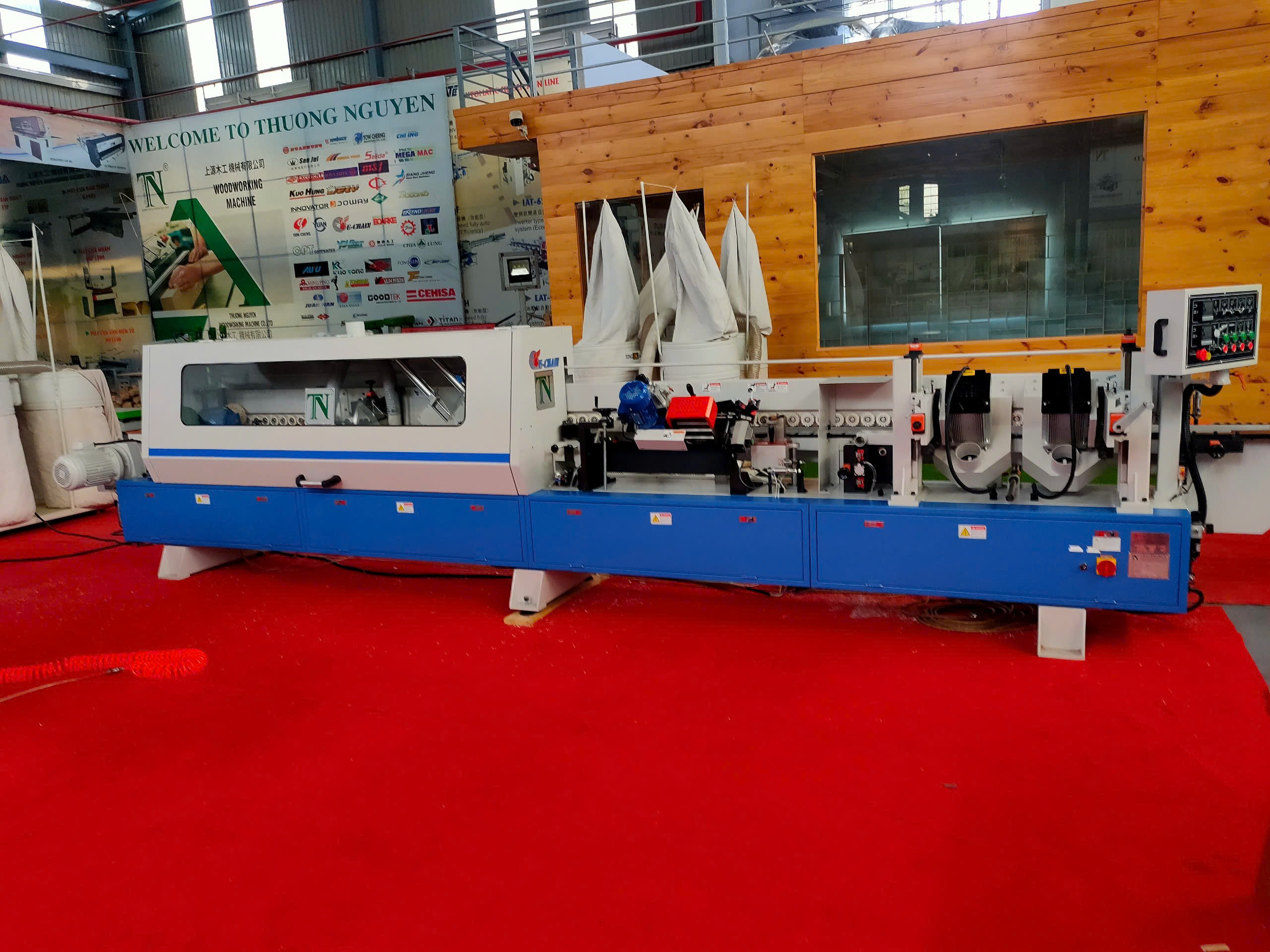

- Automatic inclined edge banding machine.

- Touch screen control.

- Has 6 functions: Milling cutting – Gluing & pressing thread – Cutting both ends of thread – Cutting top & bottom – Rounding edge – Polishing.

FUNCTION:

|

[ Premilling – Phay ]

- Mill the edge to be glued.

- Helps the edge surface to be flat, ensuring the quality of the gluing process.

|

|

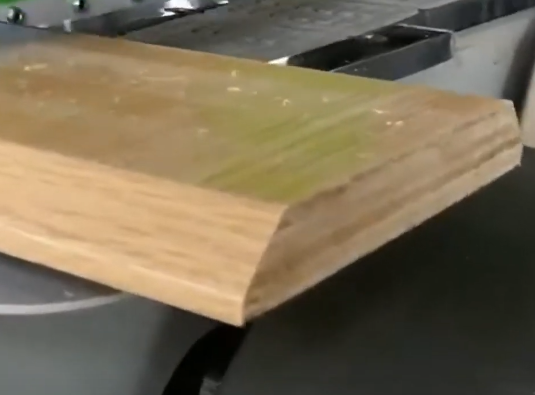

[ Gluing & Edging – Thoa Keo & Ép chỉ ]

- Glue tank. Melt the glue to apply to the edge surface to be glued.

- Roller system to press the thread into the board. Has a 45 degree inclined roller system.

|

|

[ Endtrimming – Cắt Hai Đầu Chỉ ]

- Trim off excess thread at the top and bottom of the board.

|

|

[ Trimming – Cắt Trên & Dưới ]

- Cut off excess thread from top and bottom of board.

|

|

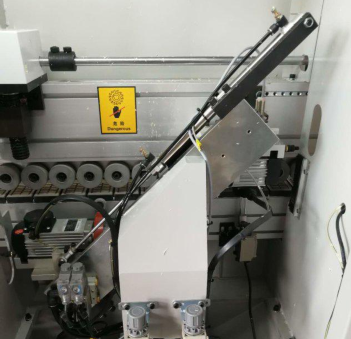

[ Radius Scrapper – Bo Cạnh ]

- Round the top and bottom edges of the board.

- Smooth the top and bottom edges, reducing the danger of sharp edges!

|

|

[ Buffing Unit – Đánh Bóng ]

- Polish top and bottom.

- Helps increase the finish and aesthetics of the product.

|

VIDEO: 45 DEGREE AUTOMATIC EDGE BANDING MACHINE

TECHNICAL SPECIFICATIONS: 45 DEGREE TILT AUTOMATIC EDGE BANDING MACHINE

MODEL: MFB-465T

| Board thickness |

12 – 25 mm |

| Lowest board width |

120 mm |

| Minimum board length |

200 mm |

| Width of the molding |

0.6 – 1.5 mm |

| Feed speed |

14 m/phút |

| Compressed air |

0.65 Mpa |

| Total capacity |

11.52 kW |

| Machine size (LxWxH) |

5080 x 900 x 1600 mm |

| Machine weight |

1560 kg |

👨🔧 Contact us now for free consultation and attractive offers!

☎️ Hotline: 0902 98 58 98

🌐 Website: https://maychebiengotn.com/

📩 Email: [email protected]

📲 Fanpage: https://www.facebook.com/maychebiengotaibinhduong

🎬 YOUTUBE CHANNEL:

– THUONG NGUYEN WOOD PROCESSING MACHINE

– WOOD PROCESSING MACHINE IN BINH DUONG