Products

- Types of Saws ❯

- Sanding Machine ❯

- Wooden machine types ❯

- Wood Jointing Machine ❯

- Wood Joiner Machine ❯

- The Sewing Machine ❯

- CNC Machine ❯

- Metal Processing Machines

- Wooden Peg Making Machine

- Drill Machine

- Lathe Machine

- Veneer Machine

- Press Machine

- Knife sharpening machine

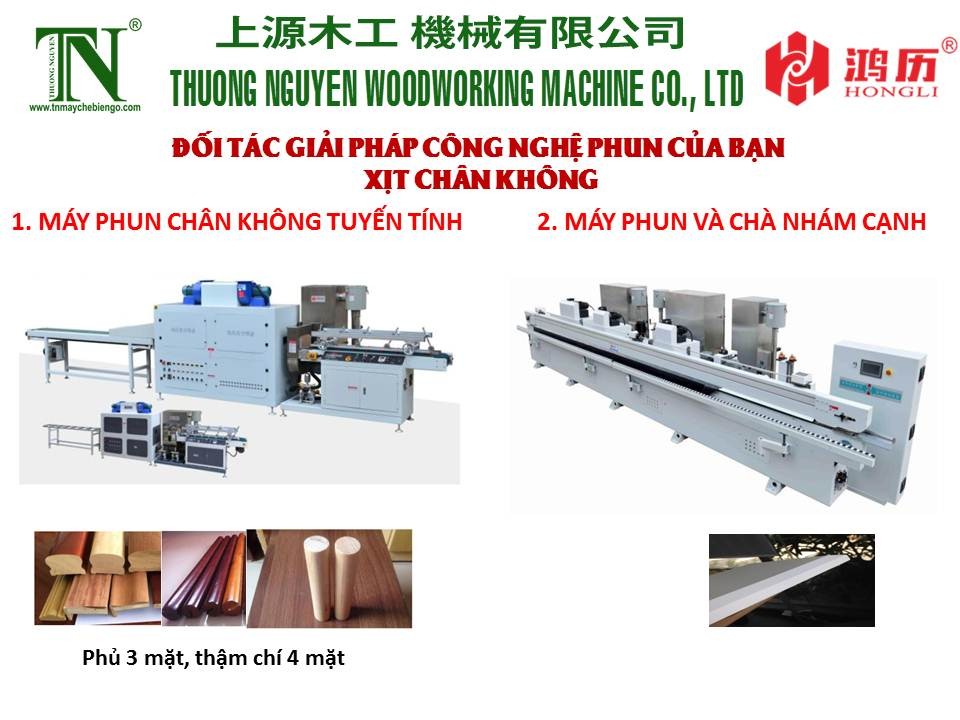

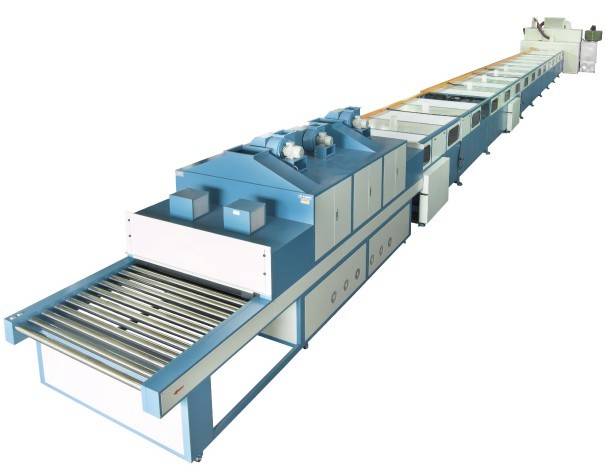

- Automatic Painting Line

- Woodworking Machine Parts

- Other Machines